Background:

Ultra-high strength steels are critical components in applications where strength and durability are important, such as agriculture, construction, mining, and even snowploughs. Because these steels are so strong, they have limited ductility, and often show undesired cracking during three-point bending. This is problematic, since bending is a critical forming process to produce components from the steel sheet.

Fig. 1: A typical application of Ultra-High Strength Steel is the front of a snowplough

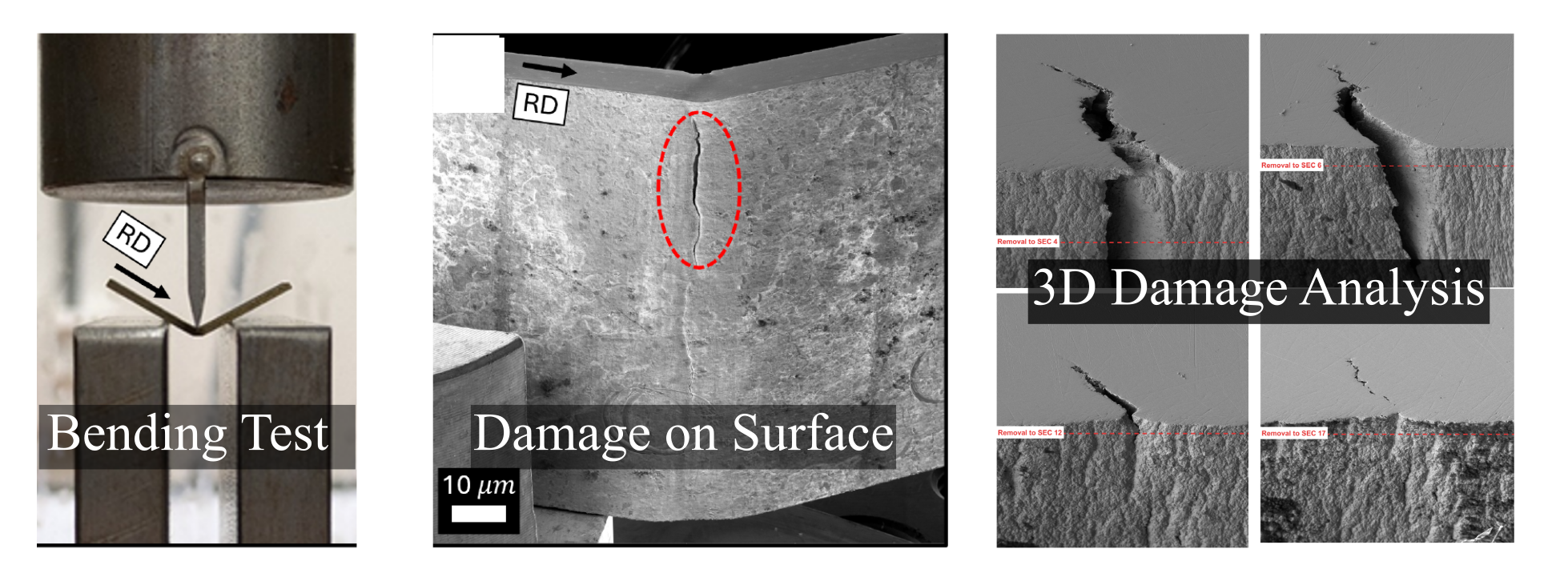

As seen in the cover image, during bending tests at the Multiscale Lab at TU/e, it was found that damage starts on the outer tensile surface, the part of the specimen that experiences the highest strains. However, the damage itself may not start at the surface, but a bit deeper in the material, owing to its complicated microstructure. This cannot be observed using optical or electron microscopy, since we only see the outer surface of our specimen.

Therefore, a method was designed to evaluate the shape of the crack (and its origin) in 3D, which involves 1) bending a specimen until failure, 2) slicing the specimen in half using electric discharge machining, and 3) iteratively remove slices of the specimen, and image it using electron microscopy. By continuously removing and imaging the material, the crack shape can be analyzed in 3D. This will allow us to learn more about the origin of failure in ultra-high strength steels, enabling us to improve their processing to prevent cracking during bending in the future.

What you will do:

Learn various experimental techniques in the Multiscale Lab, including:

Grinding and polishing of steel specimens using an automated grinding table

Imaging steel specimens using Optical Microscopy

Imaging steel specimens at high resolution using Scanning Electron Microscopy

Perform serial sectioning experiments on cracked bending specimens from different steel grades (different elemental composition), and in different directions (rolling direction and transverse direction)

Analyse your 3D damage images to unravel where and how ultra-high strength steels fail during bending.