Research Projects

Explore available research opportunities

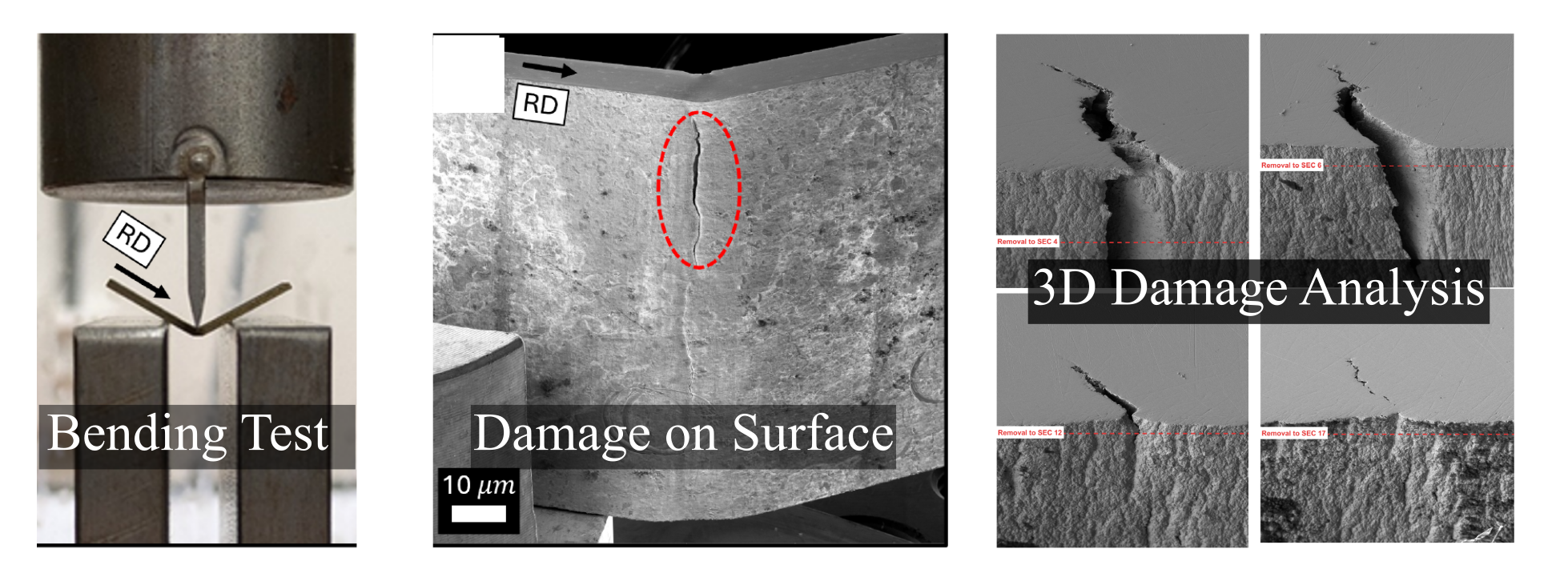

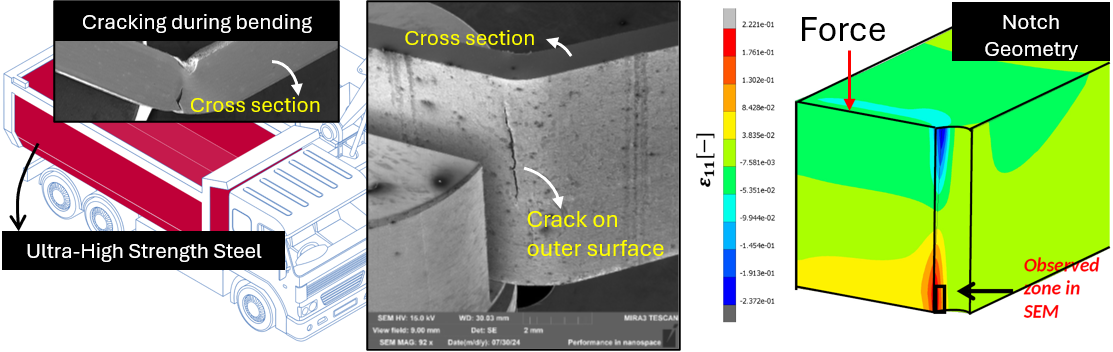

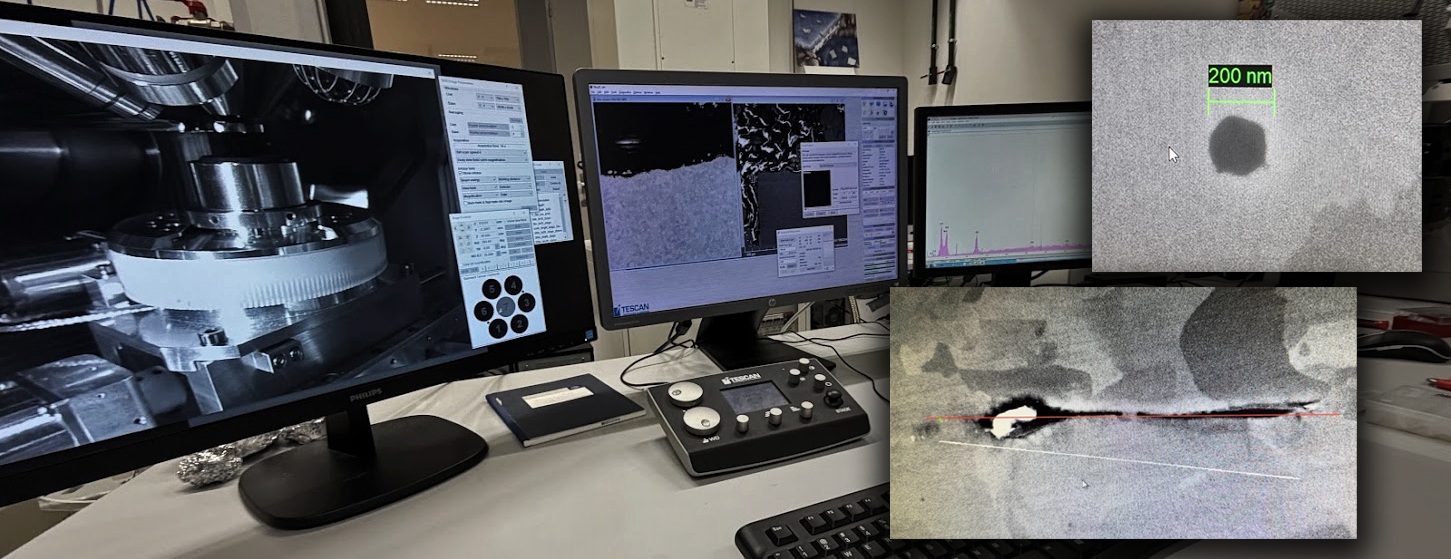

3D Damage Characterization - What's going on under the steel surface?

Cracks during bending are of critical importance, but using regular microscopy we can only see what's going on at the surface. This experimental project will focus on characterizing damage in 3D using serial sectioning and electron microscopy.

Adaptive Nerve Cuff

This project focuses on designing, fabricating, and testing conductive-polymer-based neural electrodes to enable miniaturized, biocompatible, and energy-efficient closed-loop neuroprosthetic interfaces for next-generation bioelectronic medicine.

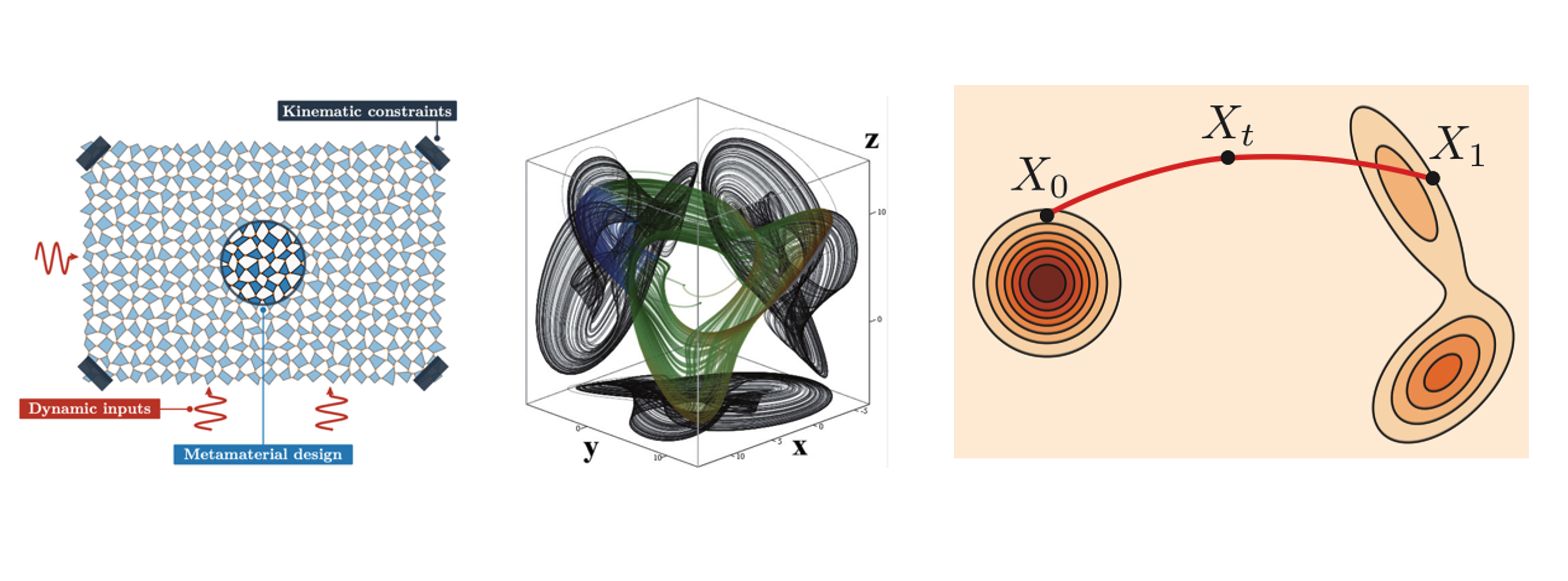

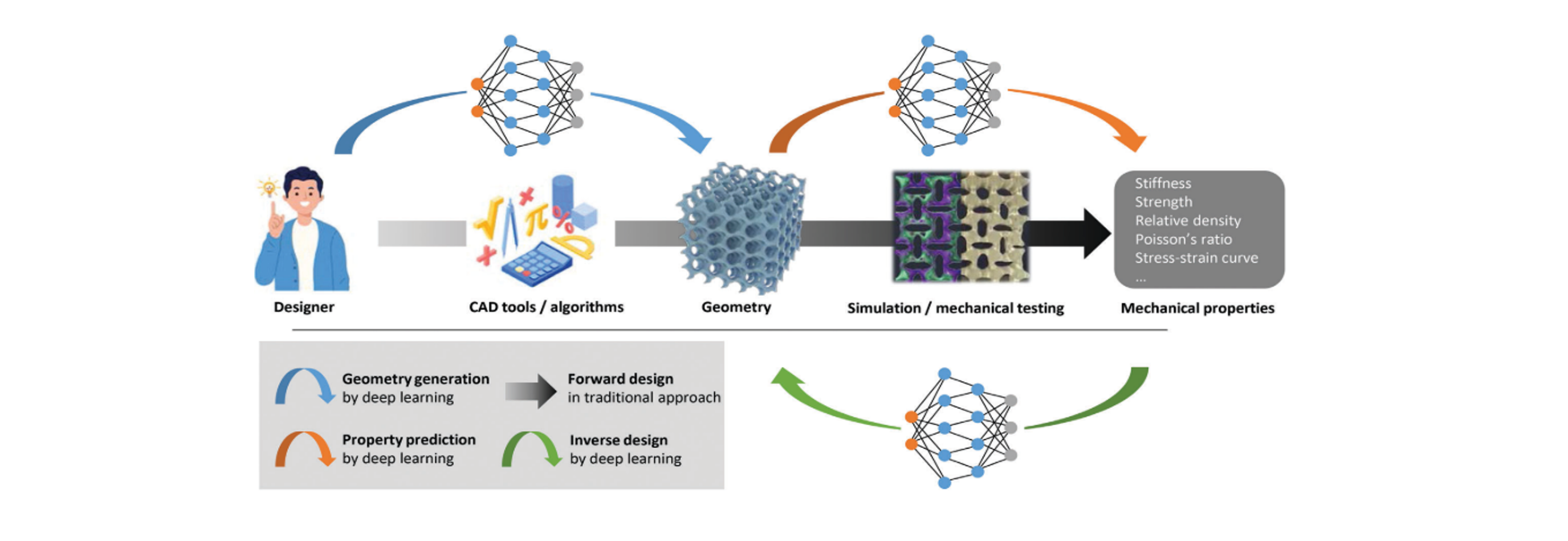

Regressing chaos through flow matching towards modelling and design of nonlinear dynamic metamaterials

Develop a machine-learning flow-matching algorithm, capable of predicting behavior of nonlinear dynamic metamaterials, allowing for design of new metamaterial structures.

Analyzing the sensitivity of a cluster dynamics model

A cluster dynamics model will be used to study the effect of neutron irradiation on the evolution of the microstructure and the resulting properties of aluminum alloys for structural components of nuclear research reactors.

A comparative assessment of additive manufacturing methods for the production of pure tungsten

A comparative assessment of different additive manufacturing processes will be conducted for pure tungsten material.

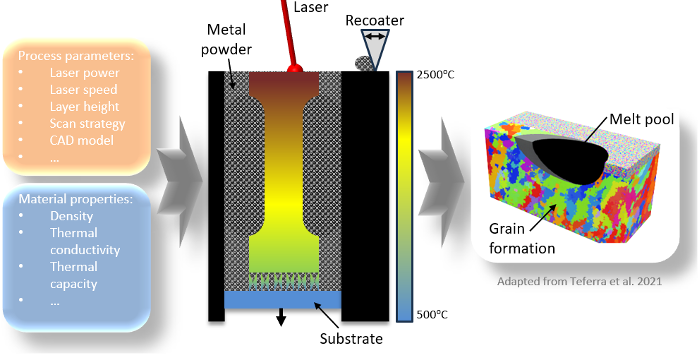

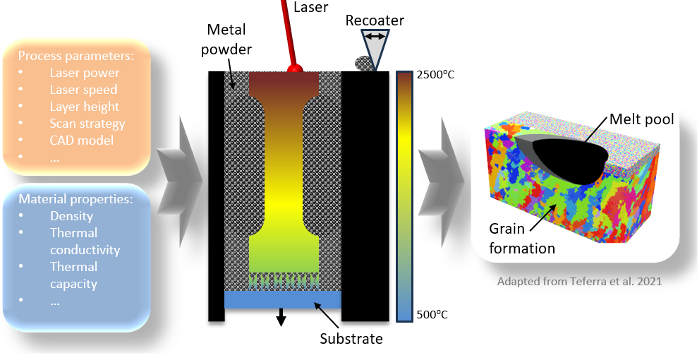

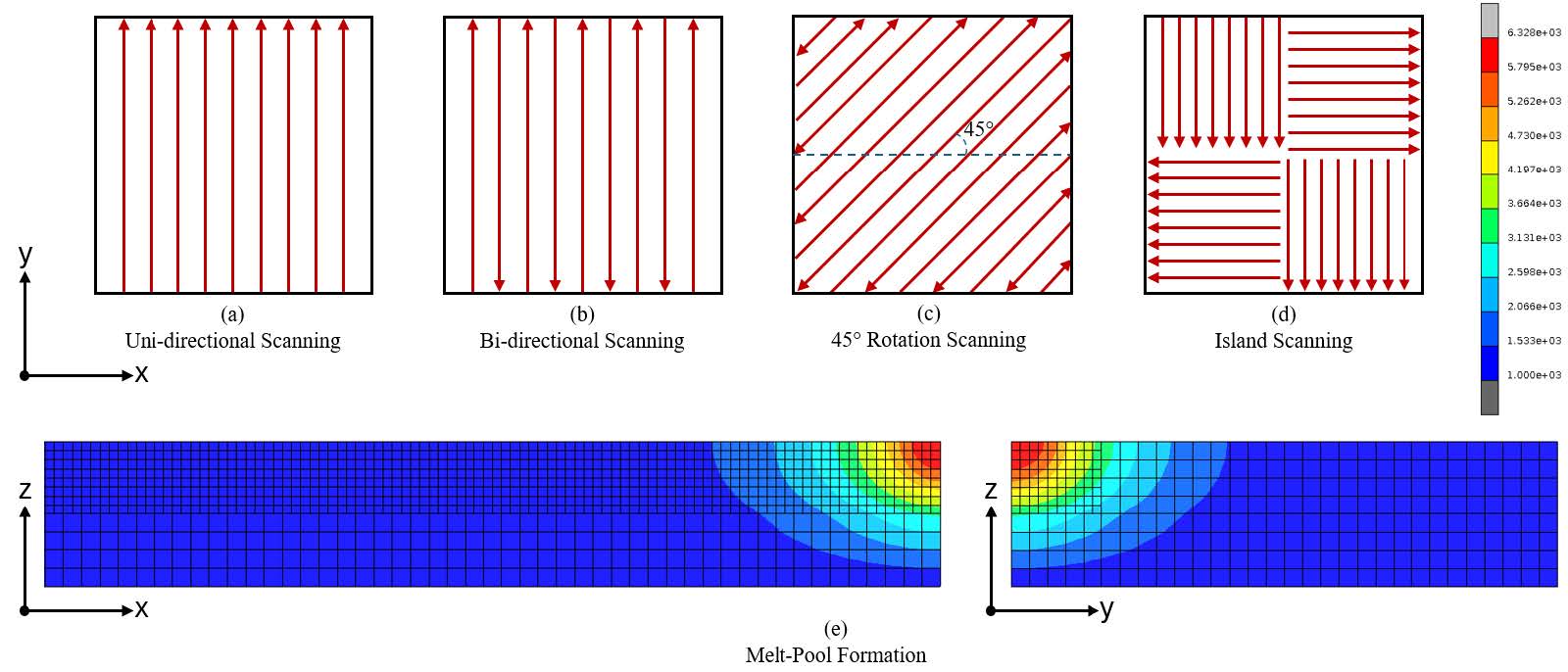

Layer by layer temprature field study of Additively Manufactured Tungsten using LPBF for Fusion Applications

A part-scale model for additive manufacturing of tungsten components for nuclear fusion applications will be developed.

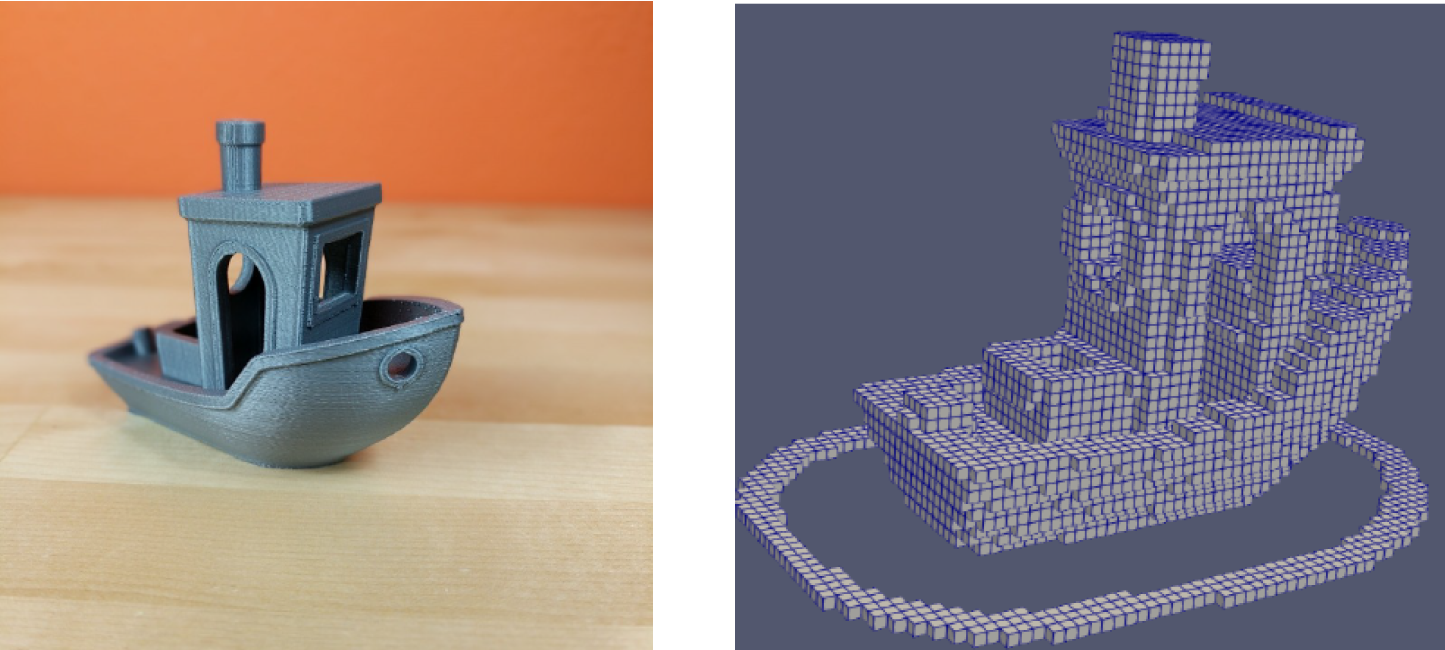

Beat the AI

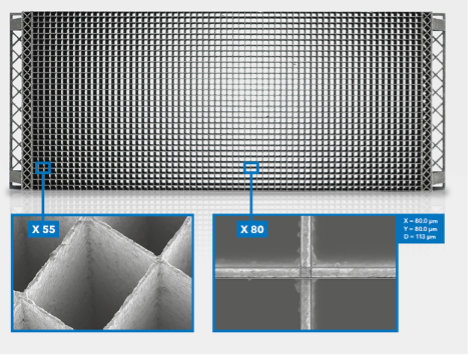

This project explores rule-based FDM infill strategies using grid models, aiming to outperform AI by reducing moves, material waste, and backtracking on complex geometries printing.

Design and implementation of a learning strategy for neuromorphic soft robots

This project develops bio-inspired learning soft robots by integrating an organic neuromorphic “brain” based on organic electrochemical transistors that process and store sensory information in hardware. Coupled to liquid crystal elastomer actuators, the system enables real-time adaptation of robotic behavior through seamless integration of sensing, learning, and actuation.

Advancing the Mesh: Enhancing Finite Element Tools for Additive Manufacturing

Enhance a Python tool converting G-code to finite-element meshes by adding belt-printer support, improving performance, and building a GUI for realistic additive manufacturing simulations research.

Numerical Study of Additively Manufactured Tungsten using LPBF for Fusion Applications

A part-scale model for additive manufacturing of tungsten components for nuclear fusion applications will be developed

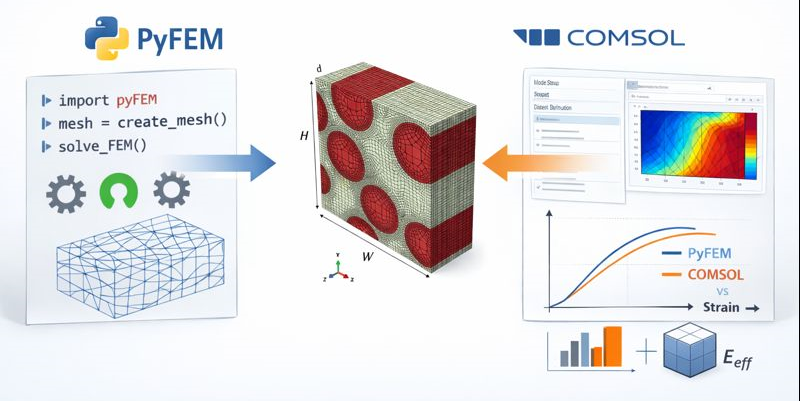

COMSOL vs PyFEM

This Bachelor project compares the open finite-element code PyFEM with the commercial software COMSOL for microstructural materials modelling. The study evaluates modelling flexibility, available material models, numerical performance, usability, and post-processing capabilities using representative homogenization-based case studies.

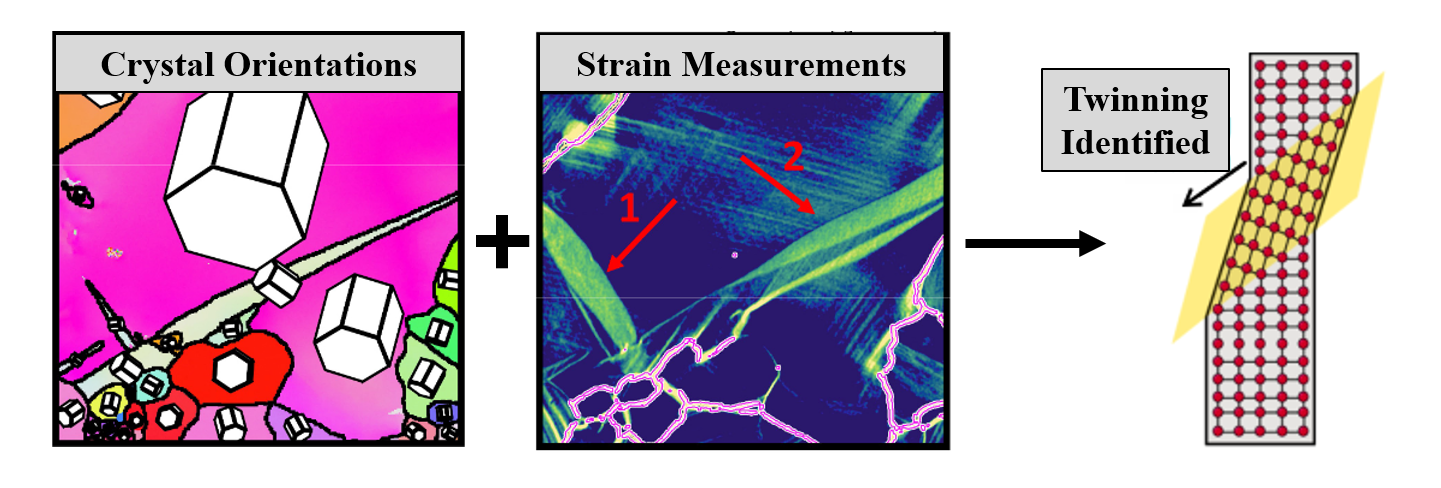

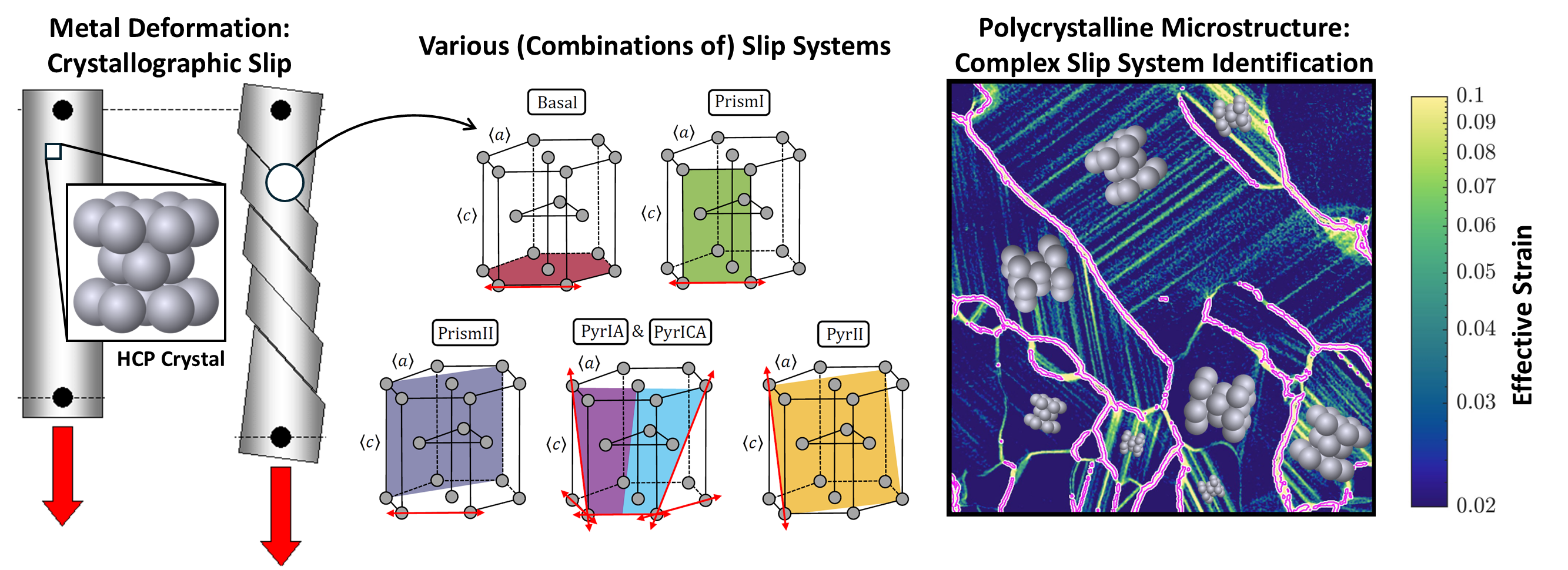

Automatic identification of “twinning” in metals on the microscale

Develop an automatic method to detect “twinning” in metals using high-resolution deformation (strain) maps and crystal orientation measurements. You’ll work with experimental & synthetic data, building on an existing Matlab slip-identification tool to design, test, and validate a new twinning-recognition approach.

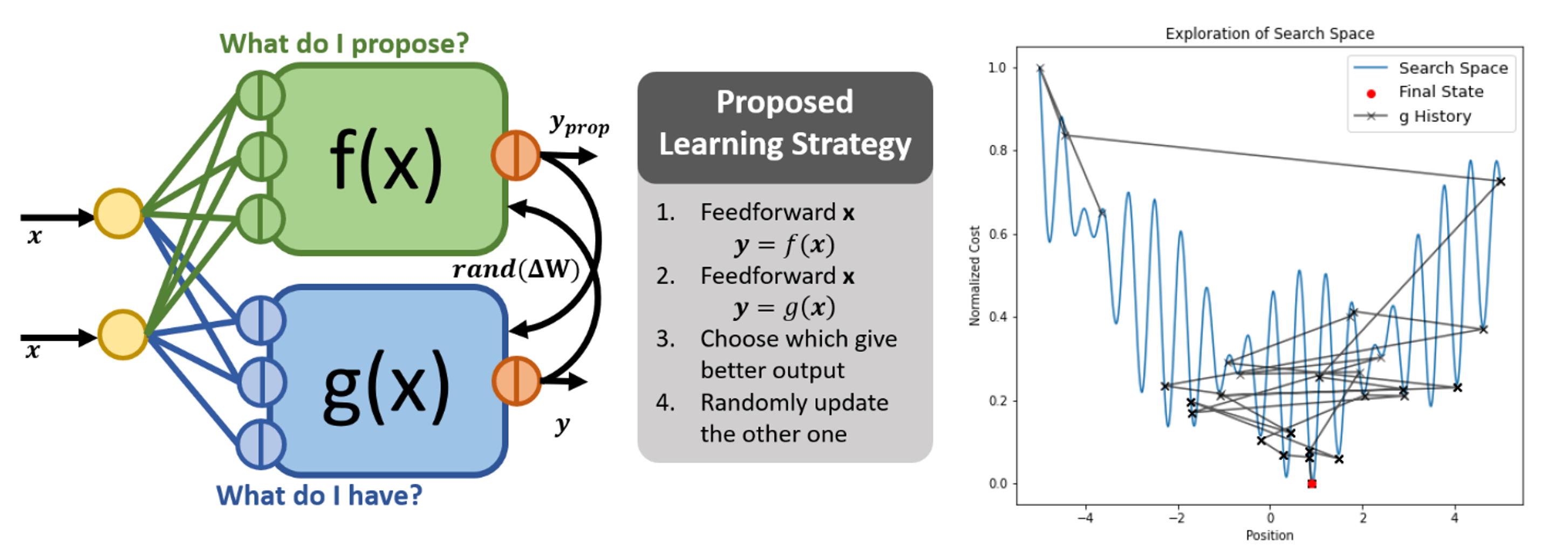

Realize Hardware based Simulated Annealing in a Hardware Based Network

This project explores energy-efficient neuromorphic learning by implementing a hardware-based simulated annealing algorithm that exploits the intrinsic physical properties of memory–processor devices. By realizing a dueling-network learning strategy directly in hardware, the system can autonomously adapt its behavior and converge toward optimal solutions without explicit knowledge of internal weights.

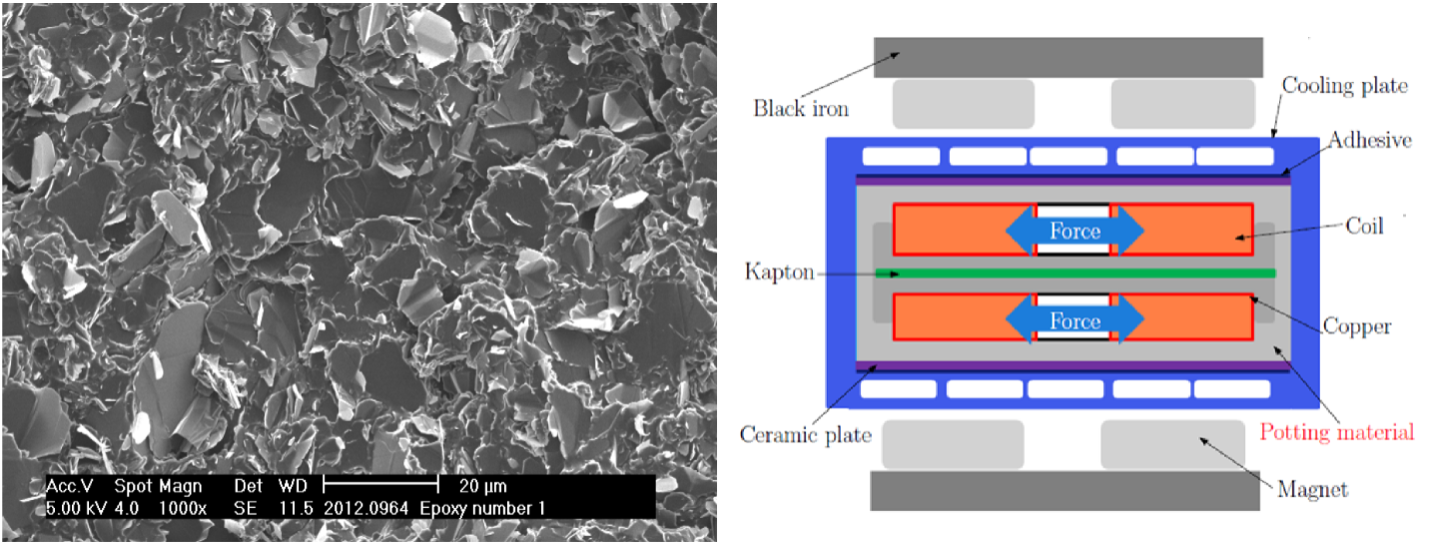

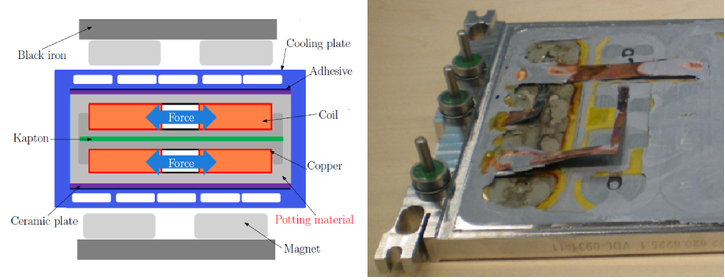

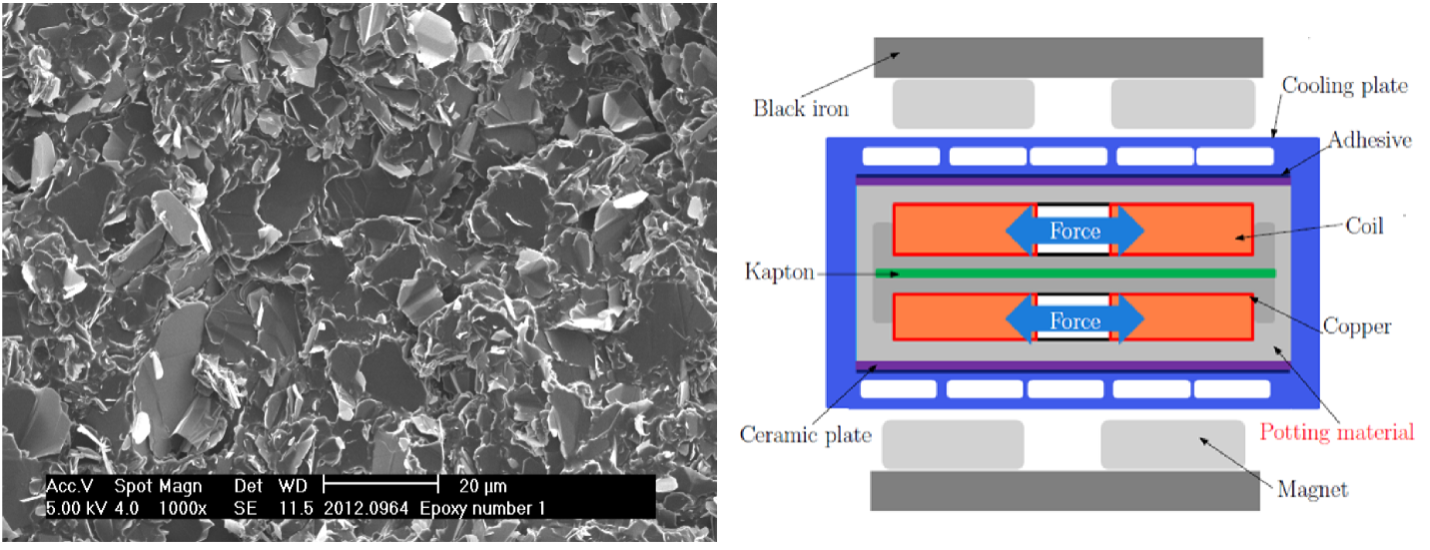

Investigation of the effective thermal conductivity & thermally induced stresses for potting material in electromagnetic actuators

Thermal conduction and the development of thermomechanical stress in heterogeneous potting material used in electromagnetic actuators is simulated using a micromechanical modelling approach.

Adaptive Organic Neural Interfacing

This project develops next-generation adaptive neuroprosthetics by using organic electronic devices to create fast, tunable, and minimally invasive neural interfaces on a single chip. By combining organic electronics, materials science, and microfabrication, the work aims to enable personalized electroceutical therapies that sense, adapt, and interact with the nervous system to improve patient outcomes.

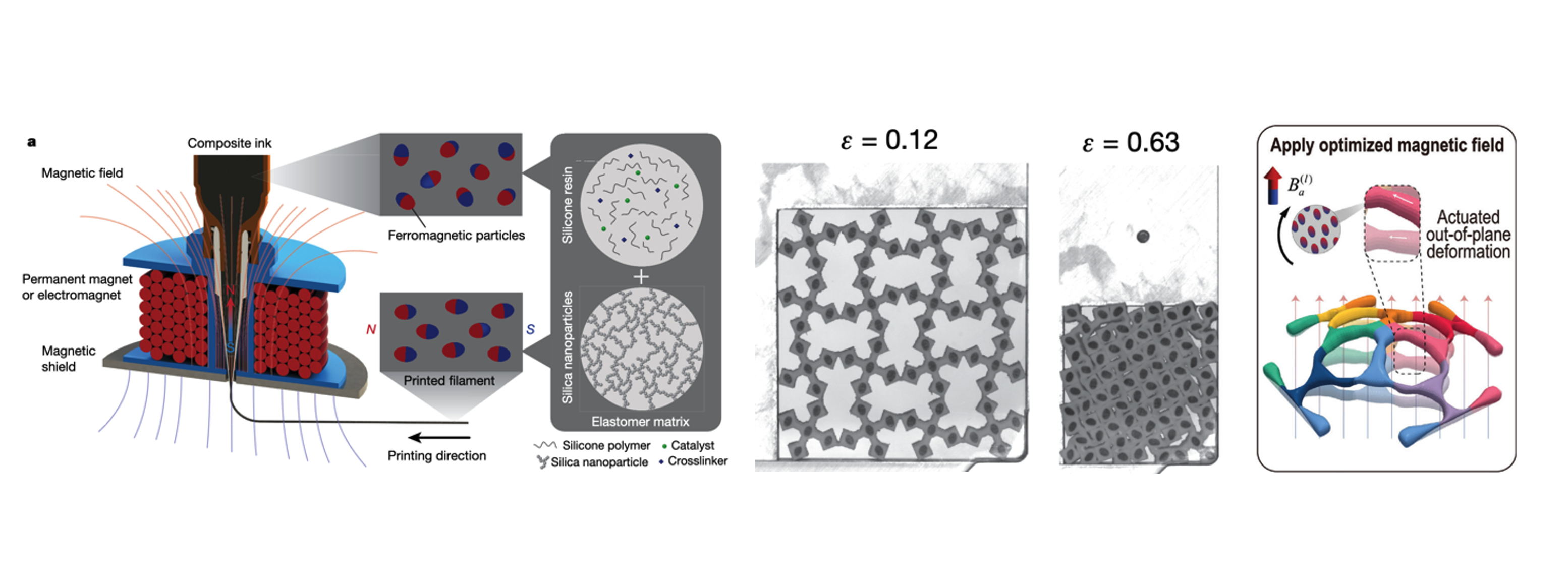

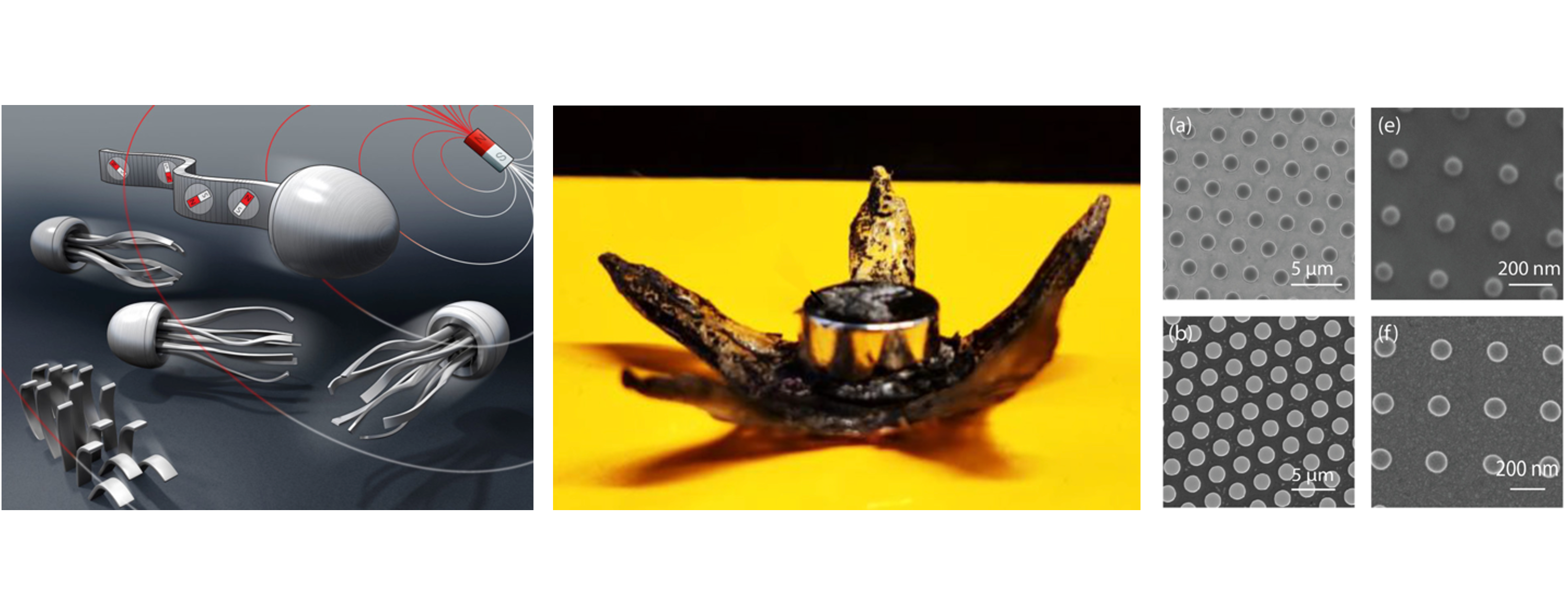

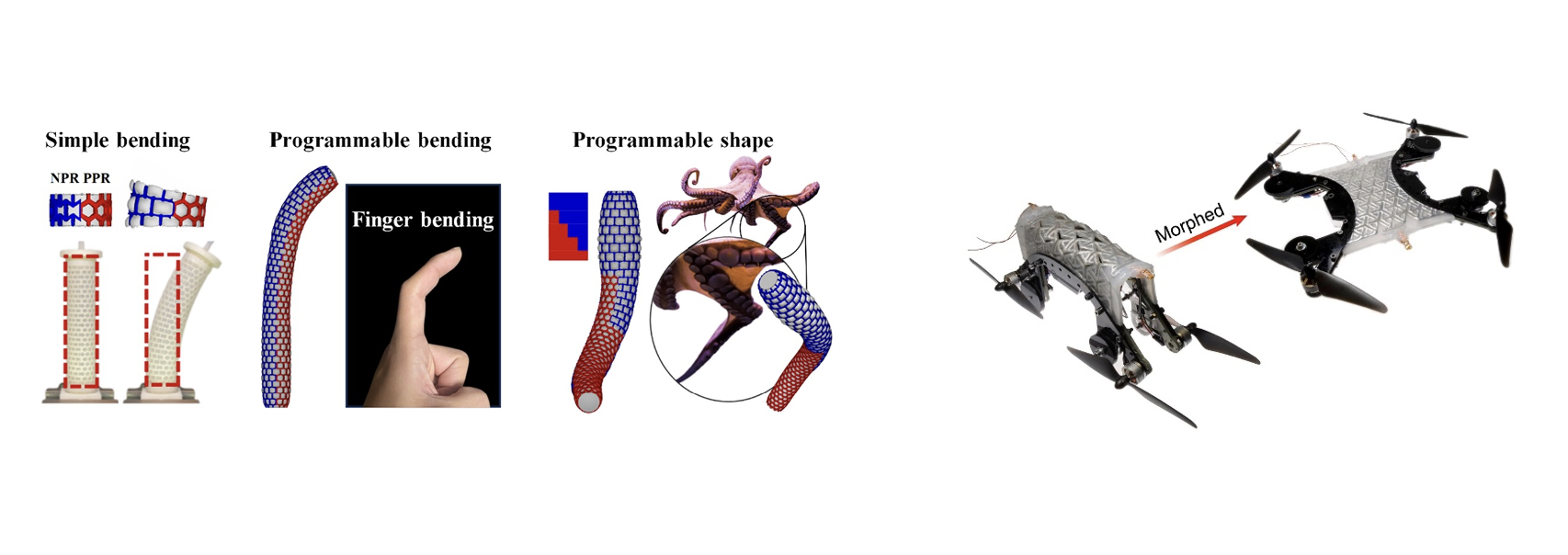

Design and manufacturing of 3D morphing scaffolds

Within this project, you will focus on computational design and additive manufacturing through 3D printing of shape-morphing scaffolds that can achieve desired shape change triggered by applications of external magnetic fields for applications in biomedical engineering.

Impact of post heat treatment on performance of 3D printed tungsten products

The impact of post heat treatment will be evaluated on microstructural and mechanical characteristics of 3D printed tungsten Anti scatter grids (ASG).

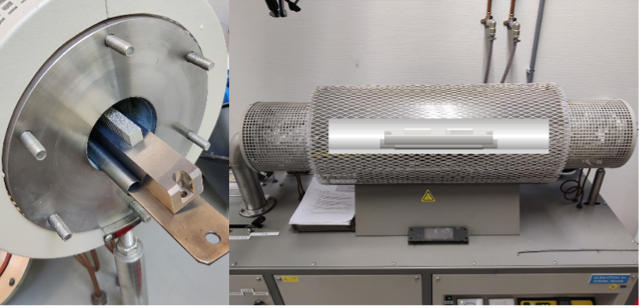

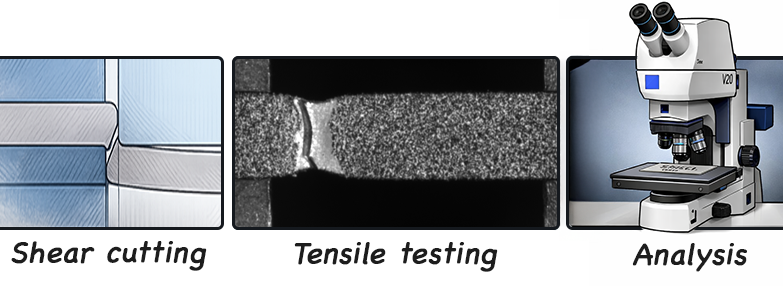

In-situ study of shear cutting effects in Advanced Green Steels

Investigate how shear cutting affects the local ductility and damage evolution of green-produced Advanced High-Strength Steels using in-situ tensile testing and optical microscopy.

Characterization of potting material + interfaces in electromagnetic actuators

The microstructure and failure mechanisms of a potting material in electromagnetic actuators are experimentally investigated.

Development of effective constitutive model for polymers actuated by antiferromagnetic nanoplatelets

Develop of a novel constitutive material model that will accurately describe combined mechanical and magnetic behaviour of rubber materials with dispersed antiferromagnetic particles.

Materials meets Machine Learning - Identifying slip systems using neural networks

Identifying crystallographic slip systems in metals is critical to understand how they deform, so we can make them more durable and sustainable. Using machine learning, you will automate this process!

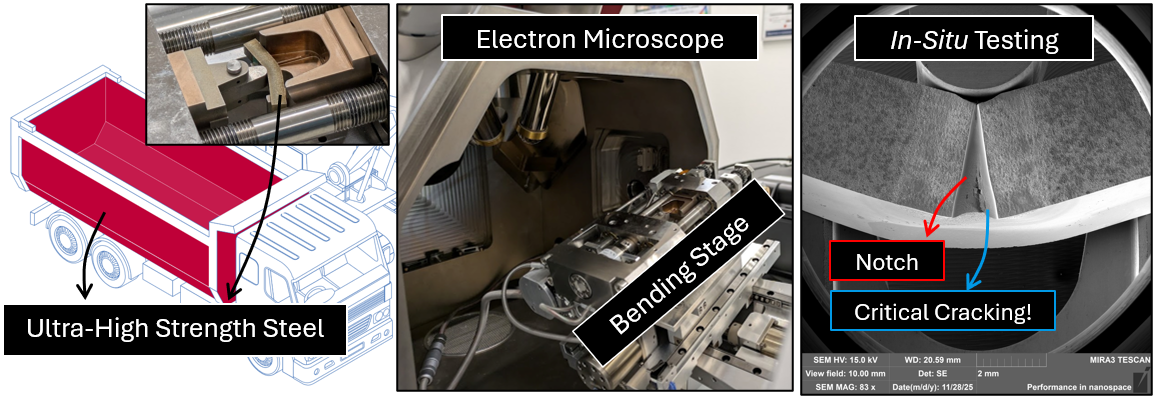

Using numerical simulations to understand (and predict!) damage in notched steel bending tests

You will employ and optimize a numerical model to understand and predict damage for notched high-strength steel bending specimens.

Micromechanical behavior of potting material for electromagnetic actuators

A fundamental understanding of the mechanical characteristics of the heterogeneous potting material in electromagnetic actuators is developed by the development and use of a numerical modelling framework.

Modelling plastic deformation in neutron irradiated aluminum alloys using mean field crystal plasticity

Microstructure evolution due to neutron irradiation of aluminum alloys used for structural components in nuclear research reactors is modelled

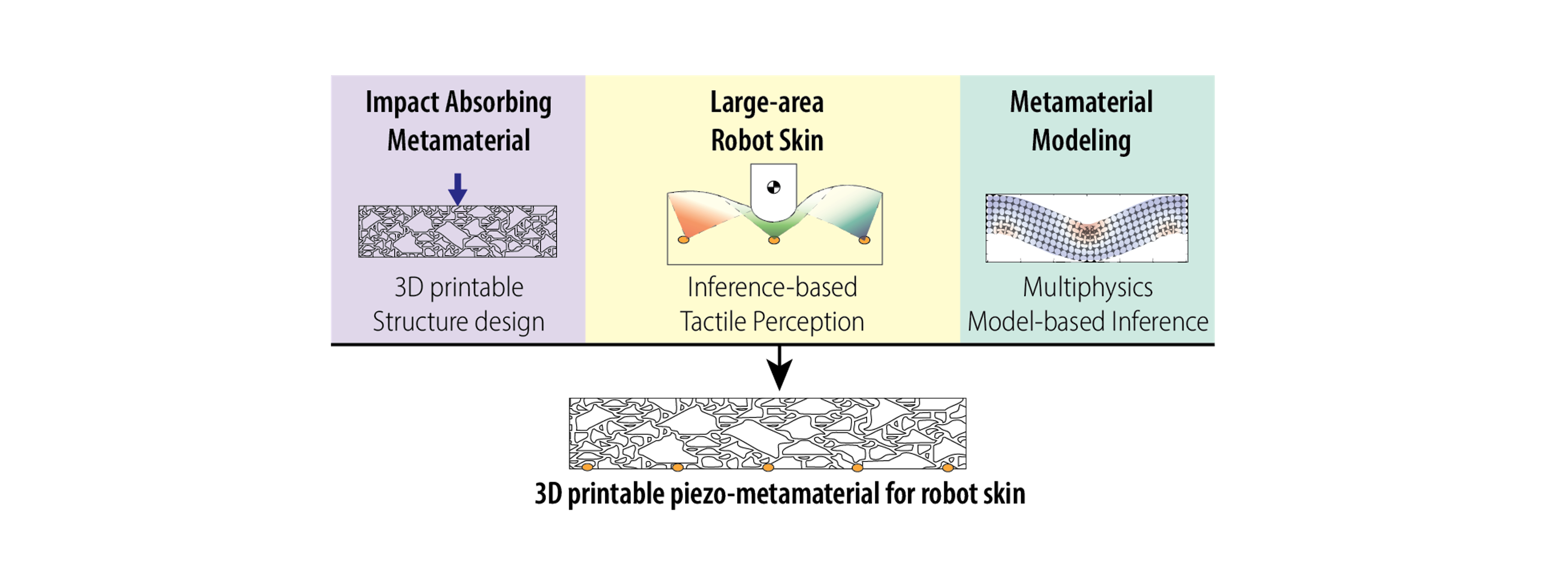

Metamaterial-Based Sensing Robot Skin

Design and development of a new class of robotic skins that will allow robots to sense and detect contact.

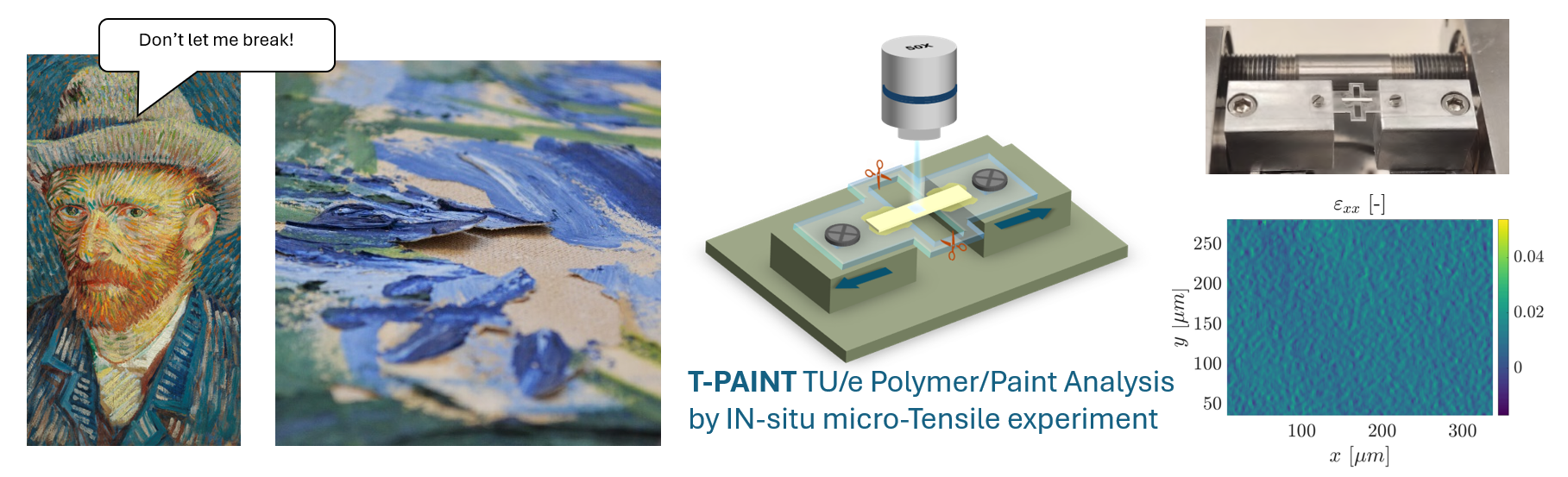

Mechanical properties of oil paints

In this project, we will apply the T-PAINT method on fragile paint samples that are currently being investigated in delamination studies, allowing us to support and clarify the mechanical failure mechanisms of the paint layers.

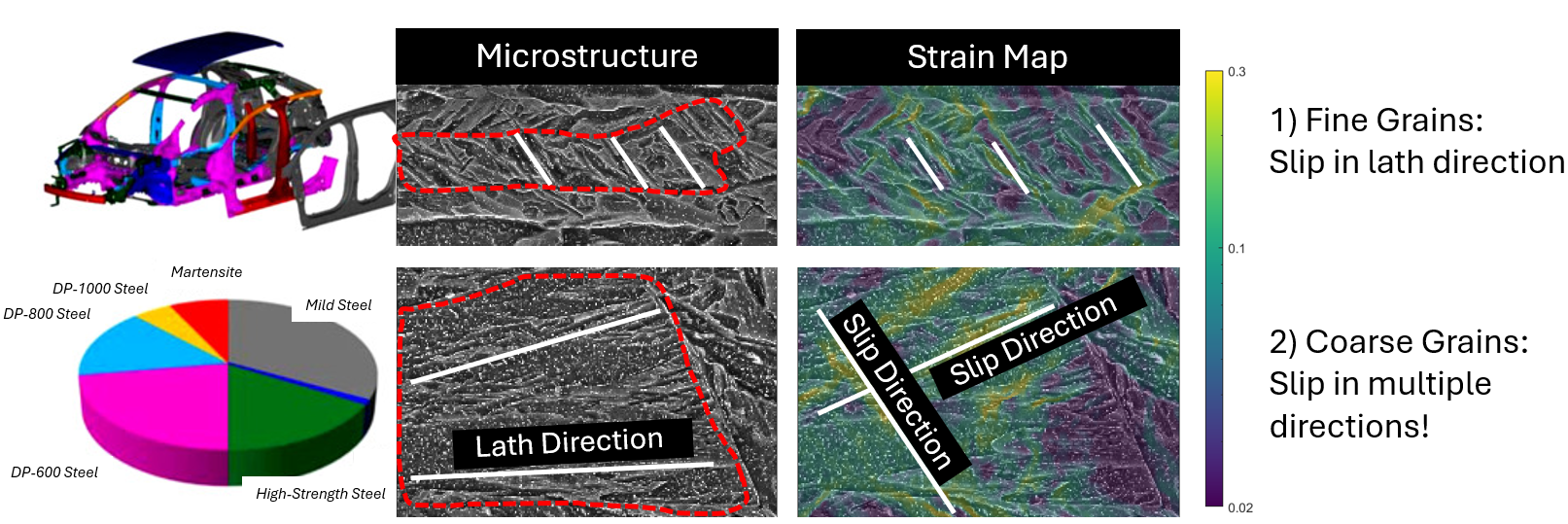

From experiment to simulation: uncovering the hidden anisotropy of martensite

Experiments show that martensite is anisotropic: its ductility strongly depends on the orientation of the crystal. Can you capture this behavior in a numerical model?

Bending at the microscale - a detailed experimental investigation

You will use high-resolution scanning electron microscopy to observe the complicated plasticity and damage evolution in high-strength steels, thereby contributing to the development of damage-resistant and sustainable steels.

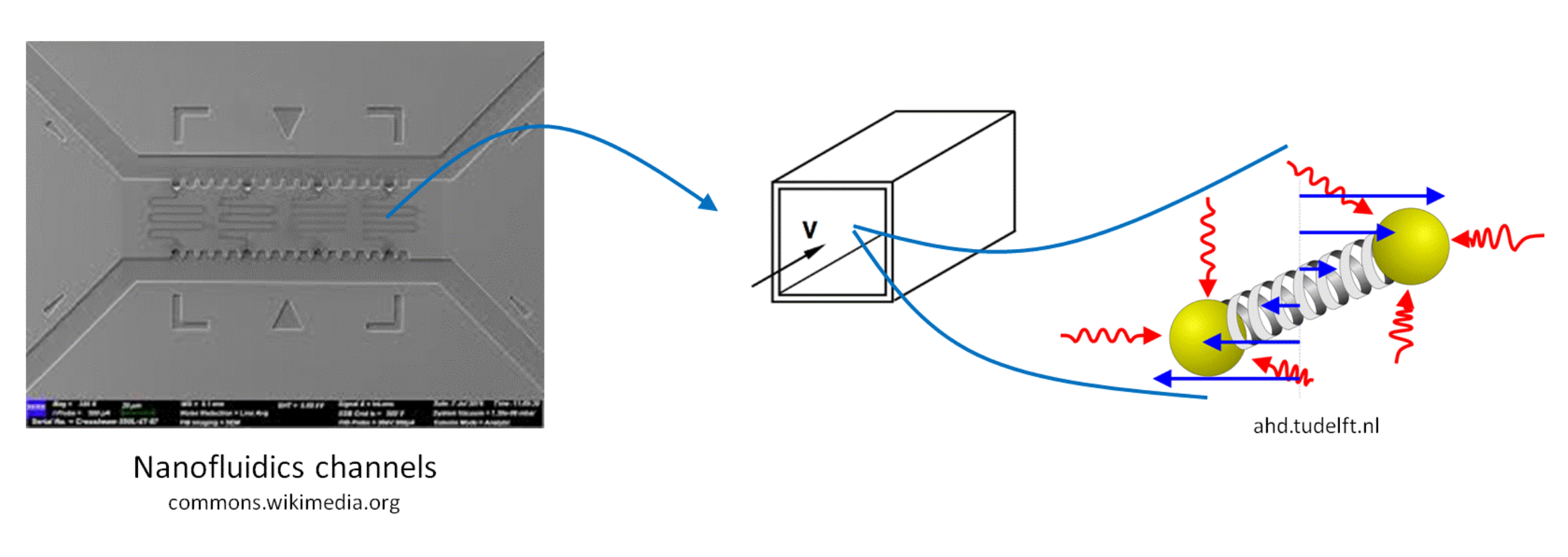

Complex Fluids in Micro- and Nano-fluidic Devices

In this project, you will develop and use finite-element simulations to study polymer solution flows in small-scale channels, accounting for thermal fluctuations and finite-size effects.

Optimizing Surface Treatments for Electron Microscopy of Green Steel

You will systematically assess and benchmark surface treatment strategies to ensure reliable SEM characterization of nanometer-scale inclusions in advanced high strength steels.

Investigating energy absorption of semi-auxetic sandwich composites

Develop autoencoder architecture for inverse design of semi-auxetics optimised for energy absorption. You will first generate training dataset using finite element method, which will be subsequently used generate new geometries with maximum toughness.

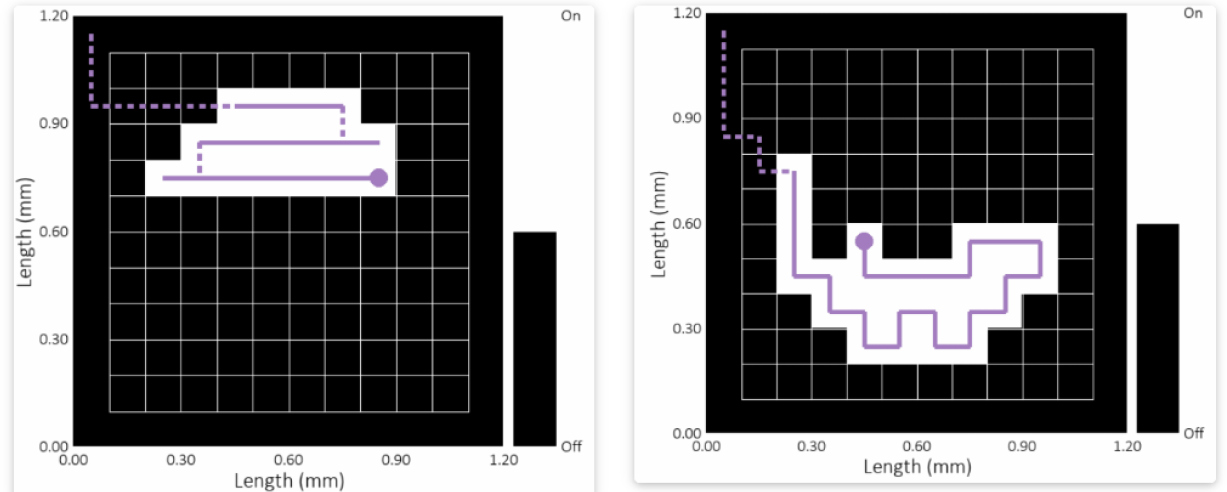

Computational Investigation of the Effect of Scanning Strategies on the Thermal Field in Laser Powder Bed Fusion of Tungsten for Nuclear Fusion Applications

A single layer finite element–based thermal model is developed and used to study the effect of different scanning strategies on the thermal field for laser powder bed fusion of tungsten.

Investigation of symmetry in mechanical metamaterials

Unraveling relationship between symmetry groups and (meta)material behavior. You will explore and understand the relationship between symmetry and mechanical properties of (meta)materials in relation to buckling.