Background:

Ultra-high strength steels are critical components in applications where strength and durability are important, such as truck beds, construction vehicles, drills, and even snowploughs. Because these steels are so strong, they have limited ductility, and often show undesired cracking during three-point bending. This is problematic, since bending is a critical forming process to produce components from the steel sheet.

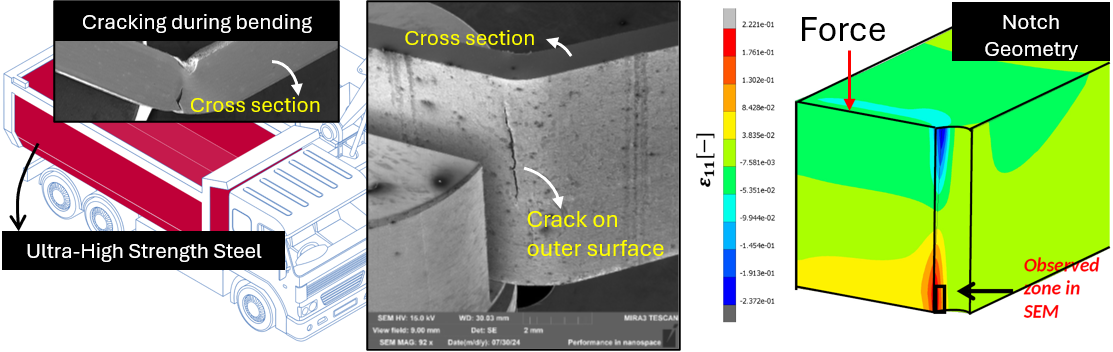

Fig. 1: A typical application of Ultra-High Strength Steel is the front of a snowplough

Several experimental and numerical projects have already been devoted to understanding the complicated deformation of these high-strength steels. As can be seen in the cover image, when specimens are bent, cracks always initiate in the center of the specimen, on the outer surface which experiences the most deformation. The damage starts here because of a ’plane strain’ stress state. On the cross section, the material can deform freely out-of-plane because of the existence of a free surface. This cannot happen in the middle of the sample, which is why the plane-strain region of the specimen is more damage-sensitive. This forms a practical problem, since during experiments (using scanning electron microscopy, SEM), we are limited to observing the cross sectional surface.

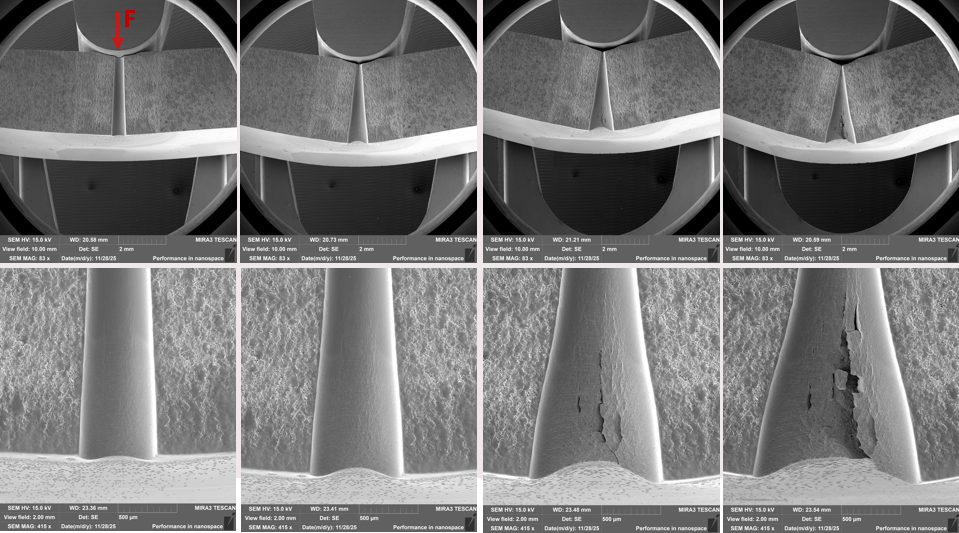

In order to observe damage nucleation on the cross section, a smart specimen geometry has been devised, using a notch to localize plastic deformation and damage. This geometry enables us to use SEM to observe the evolution of damage in a localized manner, as can be seen by the series of images below:

Fig. 2: Top-view of a bending experiment inside the SEM using a bending specimen with a notch, showing that damage localizes in the notch region

However, a lot of questions still remain, including but not limited to: Can we numerically predict where damage starts in a notched specimen? What is the stress state in the notch when damage starts, and which stress components are critical? And how does the geometry of the notch influence the occurence of damage?

This is where you come in!

What you will do:

Become acquainted with the existing model of a notched bending specimen.

Understand the strain and stress distributions in the notched specimen during deformation, and compare it to a 'regular' specimen without notch.

Learn which stress and strain measures are useful to predict damage in the notch.

Change the notch geometry (radius/shape) to tune where and how failure will initiate, thereby providing guidelines for future experiments.