Aluminum alloys containing magnesium and silicon are frequently used as structural materials in nuclear Research Reactors (RR), such as the high-flux reactor in Petten (see Fig. 1a). Over the lifetime of the reactor, these alloys absorb neutrons of various energies. Fast neutrons (high energy neutrons) cause dislocation loops and voids to form whereas thermal neutrons cause the transmutation of aluminum into silicon. The silicon then draws magnesium out of solid solution and forms Mg2Si precipitates as well as Si-rich precipitates, which are generally found on the grain boundaries.

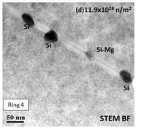

Figure 1: (a) High-flux reactor Petten (source: ANP). (b) Evolution of precipitation damage in Al 5052 with thermal fluence (source: Li et al., 2019)

A cluster dynamics model is currently being developed to simulate the precipitation and defect evolution in the aluminum alloy. The cluster dynamics model revolves around a series of differential equations which describe the growth and shrinkage of clusters such as voids and precipitates. While they are effective for large time-scale studies, they rely heavily on the accuracy of parameters. In this graduation project, the student will study the sensitivity of the model by analyzing the change in the defect evolution and precipitation kinetics with difference in parameterization and relate the irradiation conditions to the evolution of defect structure and mechanical properties of the material.