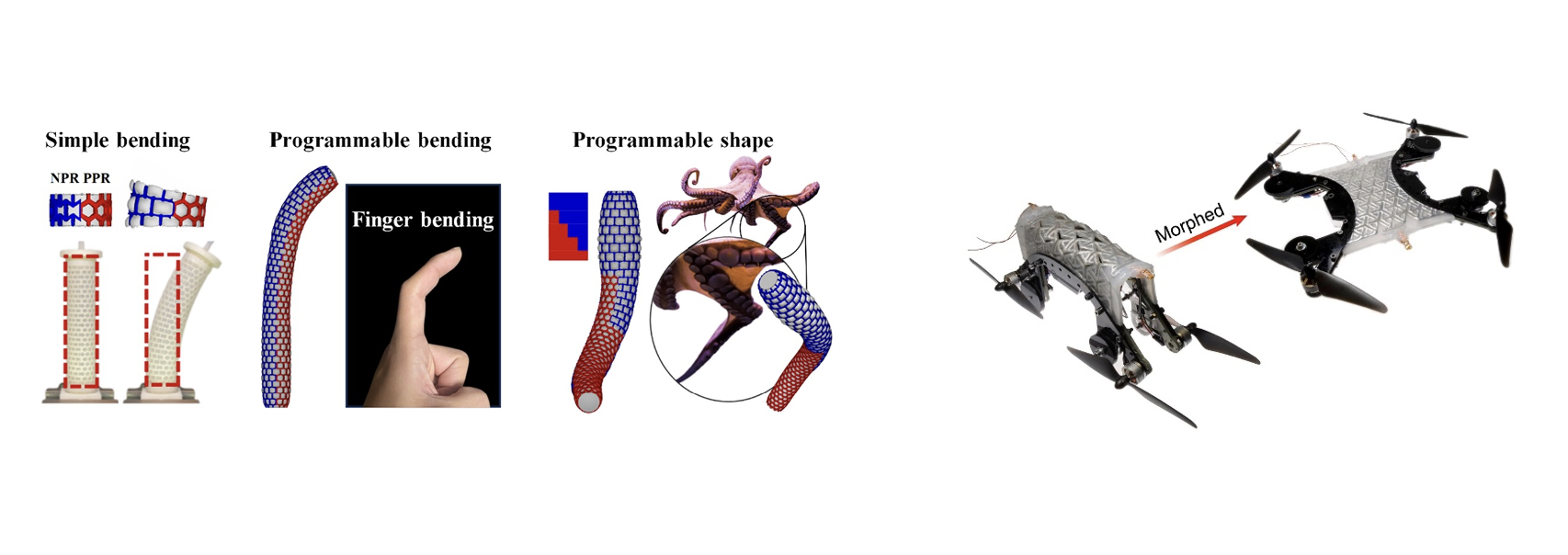

Soft robots are robots made of flexible materials, which have a lot of freedom of movement and can interact with fragile objects without damaging them. See the figure. On left [2], this figure shows types of actuators that can be created using metamaterial skins; on right [3], a drone using a metamaterial sheet to morph from a ground to air vehicle configuration is shown.

In soft robots, often mechanical metamaterials can be used. These are materials with a specific microstructure that gives them special mechanical properties. You’ll notice that a lot of metamaterials are very symmetric; the same pattern is repeated over and over, and there are multiple mirror lines.

To further optimize soft robotics, we want to investigate the relationship between symmetry groups and material behavior. Specifically, you will analyze an existing data set to understand the relationship between symmetry and mechanical properties, as well as the buckling modes [1].

This project involves the following steps:

Analyze how the mechanical properties depend on the symmetry group.

Analyze results obtained from the finite element calculations to check which symmetries are broken due to buckling, and how this depends on the loading applied.

Investigate what this means for the behavior of the material and its functionality, for example, which symmetries in the material lead to the largest number of possible buckling modes? On successful completion, the insights gained can be used to further optimize the behavior of soft robots and design new functional metamaterials.

References

[1] R. Azulay and C. Combescure, ‘Predicting the post-bifurcated patterns of architectured materials using group-theoretic tools’, Journal of the Mechanics and Physics of Solids, vol. 187, p. 105631, Jun. 2024, doi: 10.1016/j.jmps.2024.105631.

[2] Pu, Y., Zheng, S., Hu, X., Tang, S., & An, N. (2024). Robotic skins inspired by auxetic metamaterials for programmable bending of soft actuators. Materials & Design, 246, 113334.

[3] https://www.azorobotics.com/Article.aspx?ArticleID=514