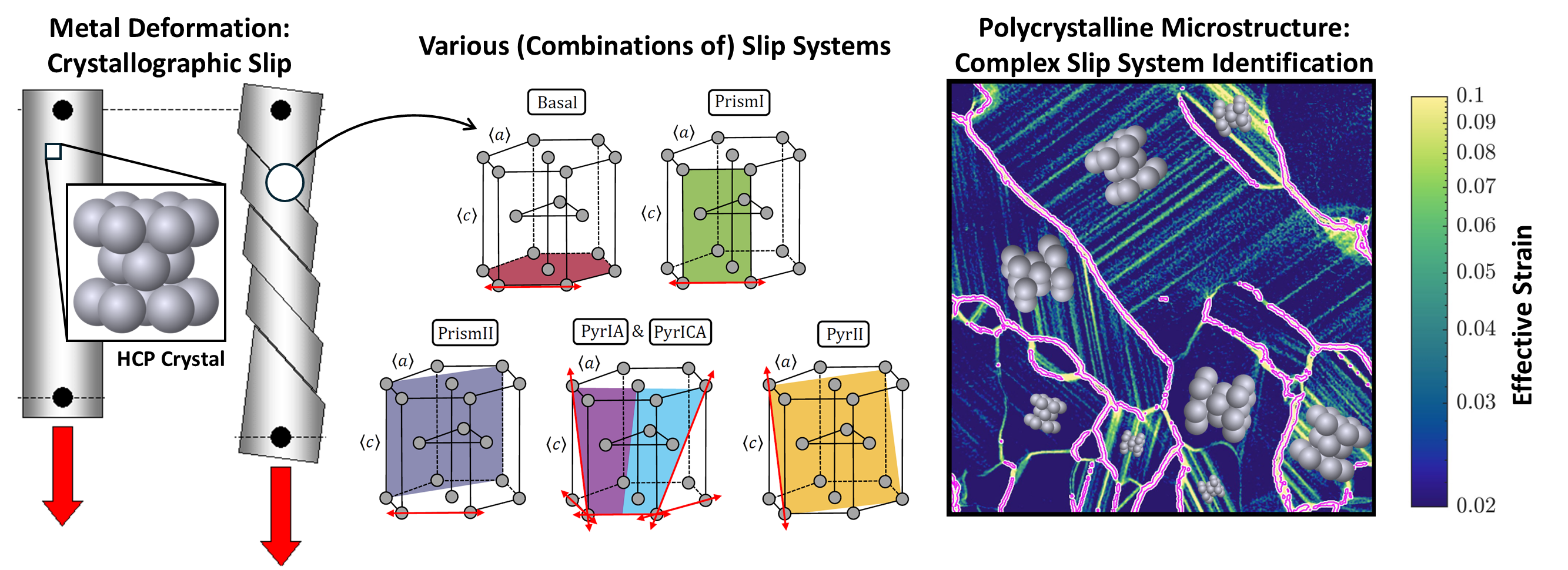

Did you think metals are old and boring? Think again! Yes, metals have been used for hundreds of years, but to this day it has been incredibly hard to identify and quantify deformations at the microscale. Plastic deformation in a metal often happens through slip of atomic planes, which can happen across many different slip systems, in particular for hexagonal close-packed (HCP) crystals as shown in the cover image. During deformation, combinations of slip activities can be observed. Identifying the types of slip can help towards understanding plasticity, and designing novel alloys.

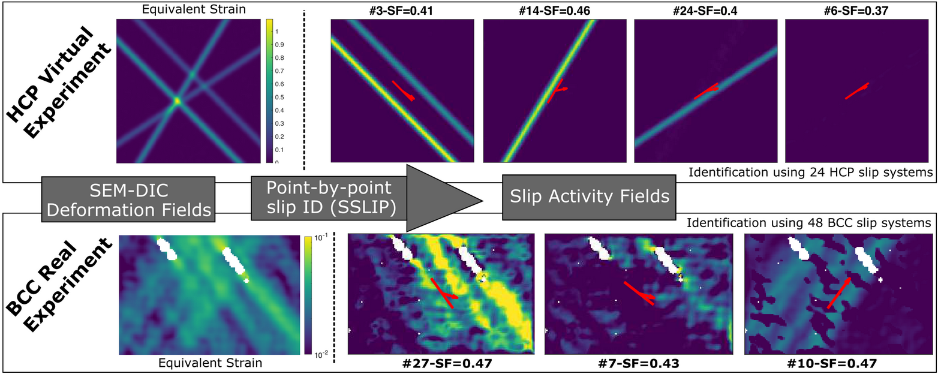

As seen in Fig. 1, a new method has recently been developed which can identify the active slip systems in any metal using experimentally obtained strain data. The method can quantify these slip activities by analyzing deformation data pixel-by-pixel, through the matching of experimentally measured deformation fields and the theoretical movements of slip systems.

Fig 1. Overview of slip system identification from experimental strain data (Vermeij et al., 2023, Vol. 243, 118502)

The slip system identification method in Fig. 1 works quite well, but is still limited, because it evaluates the data one pixel at a time (local approach). By using the surrounding data for each pixel (semi-local approach), the confidence of the solution could be greatly improved. A possible approach here is to use machine learning, since neural networks are excellent at correlating data in a small semi-local kernel, and finding relations that could be hard for humans to detect.

The objective of this project is therefore to extend the pre-existing slip system identification method shown in Fig. 1 into an automated one-step “semi-local” approach in which the local slip band orientation is included directly into the optimization algorithm.

The approach will involve (i) familiarization with the pre-existing method in Matlab, (ii) exploration and implementation of different semi-local approaches such as machine learning and (iii) validation on already available virtual (synthetic) and real experimental data.

The project offers a nice balance between open-ended algorithm/code development, fundamental crystal plasticity and application to challenging real-world experimental data.

If you are talented in coding and interested in materials science, then this is the project for you!

For more information or a chat and a coffee, send an e-mail to b.j.verhaegh@tue.nl and c.j.a.mornout@tue.nl