Background

Laser powder bed fusion (LPBF) is an additive manufacturing process, extensively used for manufacturing of variety of materials including refractory metals such as tungsten. Tungsten is a rare earth metal with exceptional properties of high density (19 g/cm3) and high melting temperature (3422 °C). Such characteristics makes tungsten a suitable material for medical (X-ray imaging) and energy (plasma-facing) applications. However, tungsten offers a considerable manufacturing challenge during the LPBF process to print a crack (micro-macro) free product specifically at high productivity. This is due to inherent characteristics of tungsten metal, which upon solidification-cooling shows a ductile-to-brittle transition (DBT).

Problem Statement & Goals

In this assignment, a comparative assessment of different additive manufacturing processes will be conducted for pure tungsten material. This assignment will comprise additive manufacturing of representative samples and subsequent characterization (mechanical and materials).

Printing trials and (part of) evaluation will be conducted at the premises of Philips Best.

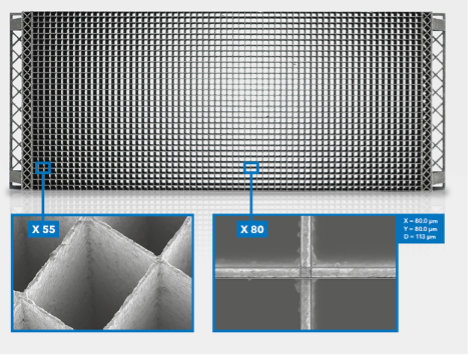

Fig.1 A tungsten antiscatter grid manufactured by laser powder bed fusion process.

This is an external project at Philips Medical Systems