Additive manufacturing, particularly fused deposition modeling (FDM) 3D printing, relies on carefully planned toolpaths to deposit molten material layer by layer. Within each layer, the internal “infill” structure is generated by tracing a path over the build area: this infill pattern directly affects how fast the printer runs, how much filament is used, the final part’s strength under load, and the smoothness of its surfaces. Poorly chosen infill can cause the nozzle to retrace its steps, waste time and material, or leave gaps in thin features.

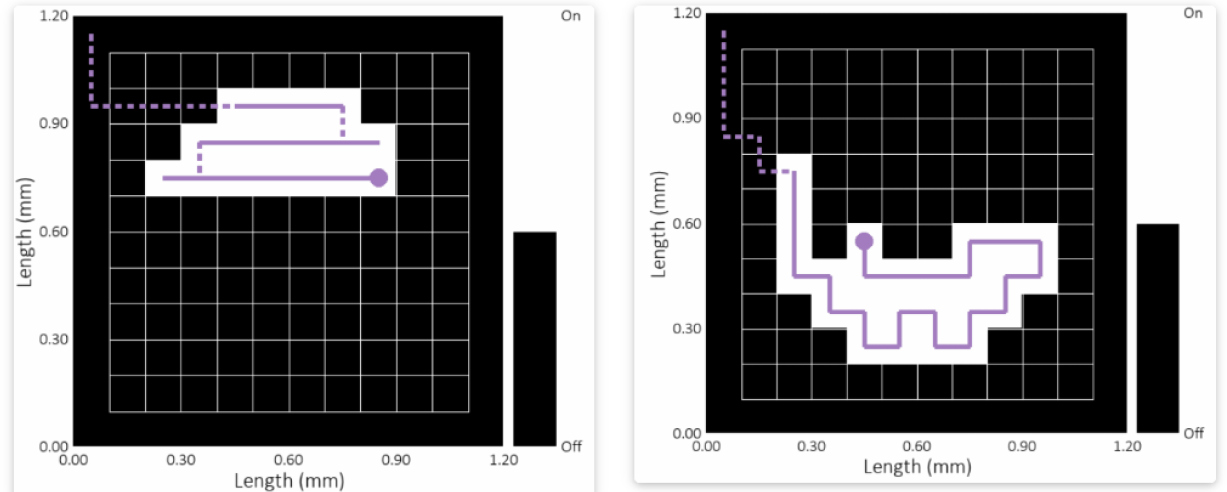

Our framework simplifies infill generation into a 2D grid model where a virtual pointer can move one cell at a time and toggle its fill state on or off. We impose strict limits on the total number of moves and forbid revisiting already filled cells, so every step must count. A basic zigzag pattern simply sweeps back and forth, turning the source on at the start of each row and off at the end—but it struggles with curves and narrow passages, resulting in extra travel. In contrast, our AI method learns to choose each move strategically, beating zigzag on new shapes by using significantly fewer moves and avoiding needless backtracking—while simpler, handcrafted rules (spirals, edgefollowing, etc.) have yet to be explored.

Your goal is to develop straightforward, rule-based infill strategies that outperform the AI agent on new, complex geometries. Focus on heuristic patterns such as spiral sweeps, boundary tracing, or region partitioning.