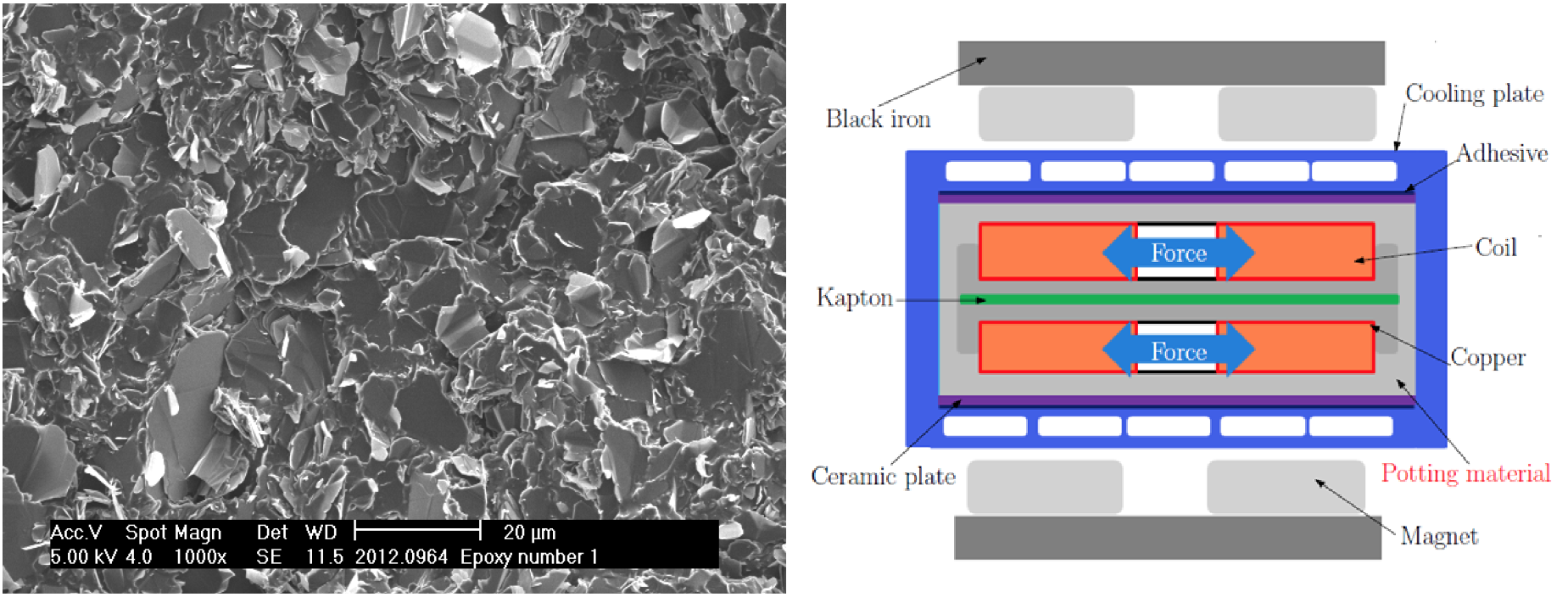

In actively-cooled electromagnetic actuators, as used in for example the EUV lithography machines from ASML, layers of epoxy-based potting material serve, among other things, for the dissipation of heat to the outside of the actuator. Given this purpose, the effective thermal conductivity of this material is of vital importance for actuator performance and longevity.

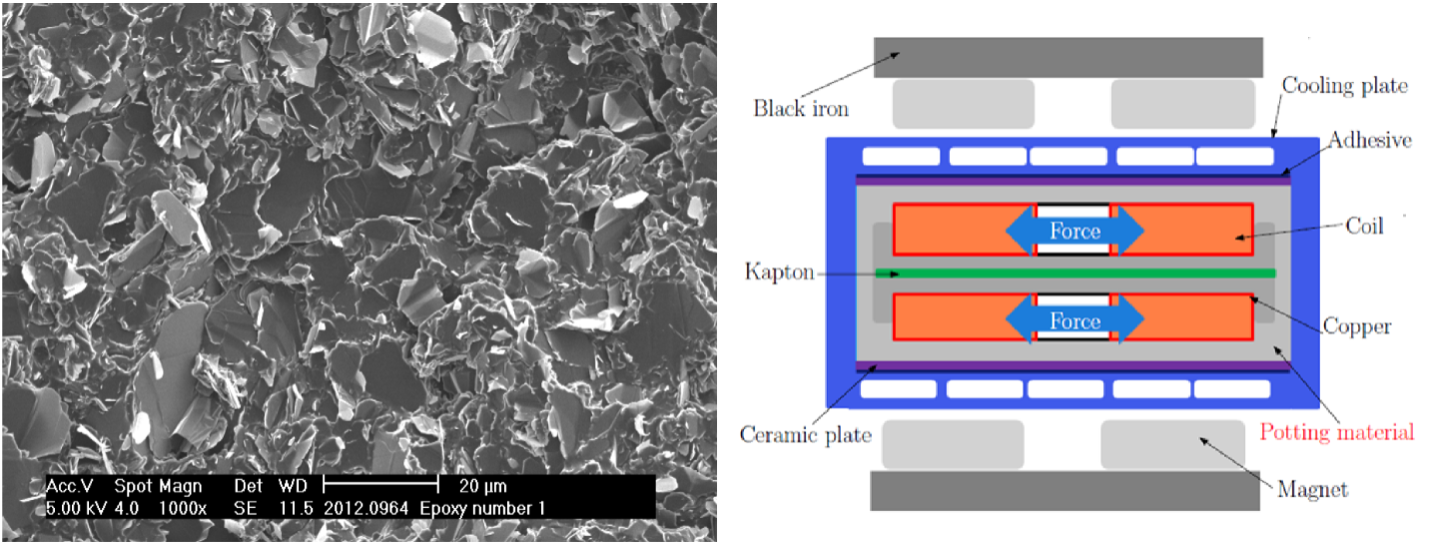

To improve the thermal conductivity of the potting material, its epoxy matrix is filled with boron nitride platelets. Due to the heterogeneity introduced by this, variations in platelet size, shape, orientation and geometrical distribution at the microscale are all expected to have an influence on the effective thermal conductivity of this material. The first goal of this project is to numerically investigate these effects via finite element modeling. Second, the thermal stresses induced by differences in the thermal expansion coefficient for the epoxy matrix and boron nitride platelets will also be studied using the same numerical framework. As a starting point, a basic modeling workflow in combination with a microstructure generator and meshing procedure has already been developed.

Figure 1: SEM image of the heterogeneous potting material (left) and a schematic representation of an electromagnetic actuator cross-section (right).