The transition towards green steel production routes, such as hydrogen-based direct reduced iron (DRI) combined with electric arc furnace (EAF) processing, is essential for reducing CO₂ emissions in the steel industry. These routes, often combined with increased recycling content, introduce distinct microstructural features in advanced high-strength steels (AHSS). While the bulk mechanical properties of such green-produced AHSS are increasingly studied, much less is known about how these materials respond locally to manufacturing operations.

Shear cutting (blanking) is a common industrial process in the forming of AHSS components and is known to introduce severe local deformation and damage at cut edges. This local damage can significantly reduce edge ductility and increase the risk of edge cracking during subsequent forming operations. For green-produced AHSS, the interaction between shear cutting–induced damage and microstructural features originating from hydrogen-based steelmaking routes remains largely unexplored.

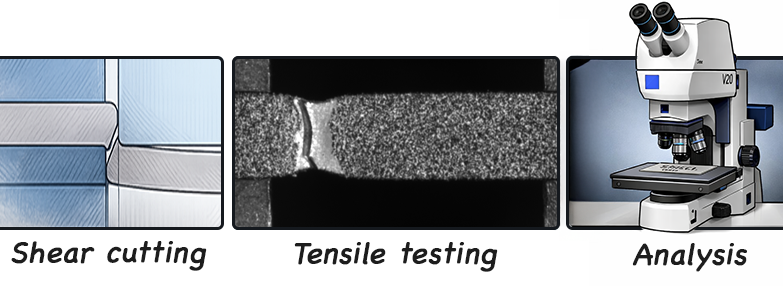

In this bachelor project, you will investigate how shear cutting affects the local ductility of green-produced AHSS. Controlled laboratory trial steels will be used, designed to mimic the EAF–DRI hydrogen steelmaking route and incorporating recycling content. You will test tensile specimens with well-defined shear-cut edges, enabling a systematic study of the combined effects of green steelmaking and shear cutting.

The experimental work is highly hands-on and includes specimen preparation, mechanical testing, and analysis. Uniaxial tensile tests will be performed on shear-cut coupons while monitoring stress and strain. Deformation and fracture near the cut edge will be studied using in-situ optical microscopy with a ZEISS V20 microscope, allowing direct observation of damage evolution during loading. The analysis will focus primarily on qualitative assessment of local deformation, damage initiation, and fracture behavior, supported by mechanical test data.

The outcomes of this project will contribute to a better understanding of edge ductility and edge cracking risks in green-produced AHSS. Given the widespread use of AHSS in the automotive industry, these insights are directly relevant for improving forming robustness and supporting emission reduction efforts in sustainable automotive manufacturing.