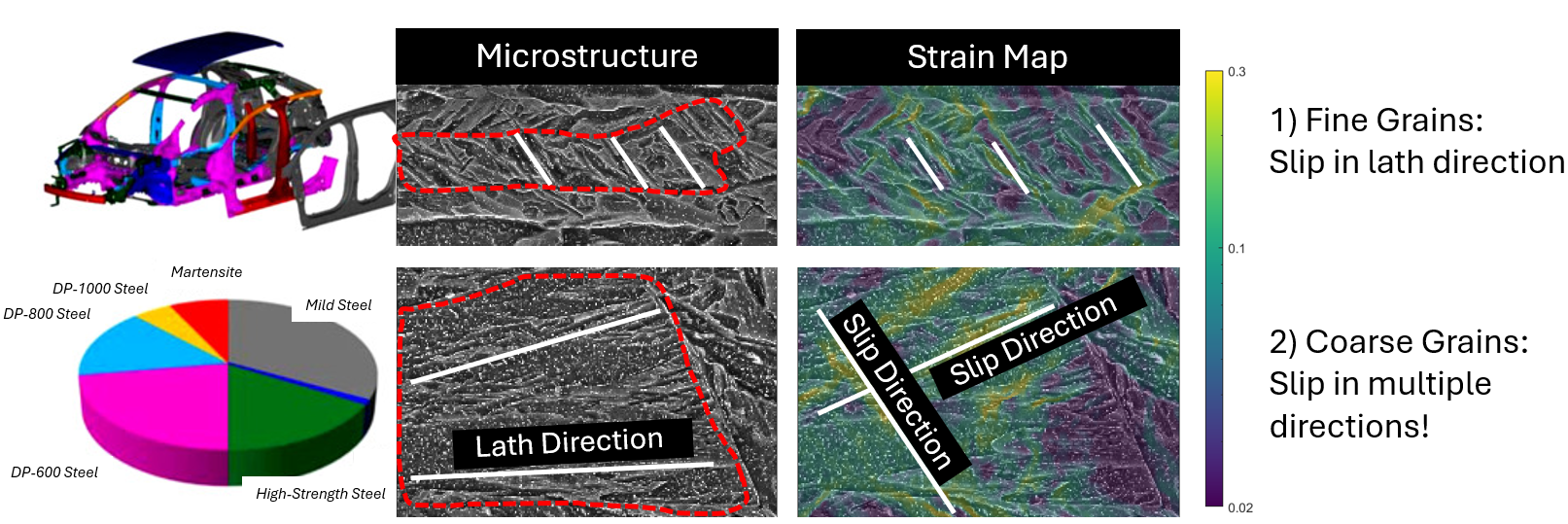

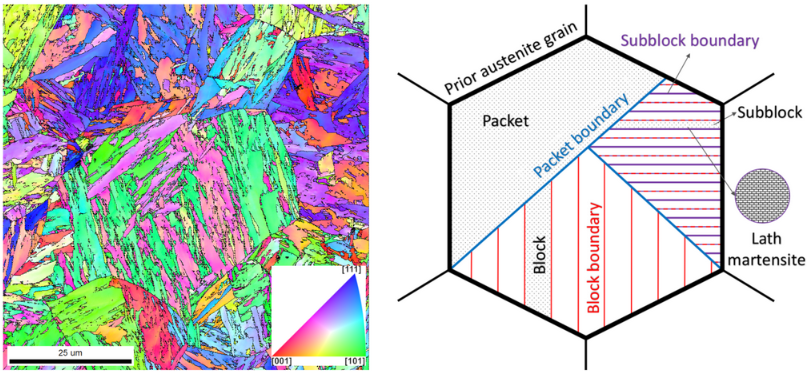

When steel is cooled rapidly, martensite forms. Martensite is a hard and brittle type of steel which consists of a lath-like structure on the nanoscale. Both martensite, and the combination of martensite with the softer phase ferrite (Dual-Phase / DP steel), are critical car components, as shown in the cover image. An image of the martensite microstructure, showing the long laths, is shown below:

Fig 1. The microstructure of lath martensite (Gallardo-Basile et. al, Materials, 2021, 14(3), 691)

The brittleness of martensite causes it to crack under deformation and this has a critical influence on the failure of DP steels. However, recent research has shown that martensite can be surprisingly ductile, in particular, by sliding along the lath direction. In other words, the martensite ductility is dependent on orientation and is therefore highly anisotropic. However, the extent of this anisotropy, as well as the conditions under which it develops, are not yet fully understood.

An important factor in martensite anisotropy is the size of the lath. Some martensite types have a fine lath substructure, whereas others have coarser laths. Experimentally, it was observed that coarse-lath martensite can slip more easily in various directions, meaning less anisotropy and more ductility. The comparison between fine and coarse martensite is shown in the cover image, where we can see that slip along multiple directions is possible for coarse lath martensite. Finding the relation between martensite lath size and anisotropy, and capturing this in numerical simulations, is a critical step in making the next generation of martensitic steels more damage-resistant and safe / versatile.

Therefore, we are looking for a student that is passionate about data analysis and coding, who is ready to uncover the hidden martensite anisotropy by analysis of experiments and numerical simulation.

What you will do:

Analyze the relation between martensite plasticity and lath size:

1) Analyze strain maps and active slip systems from various experiments (using the MTEX Toolbox in Matlab)

2) Create a smart image processing tool to calculate the corresponding martensite lath size

3) Uncover the relationship between martensite lath size, and martensite plasticity

Capture your findings in numerical simulations and calibrate your model so it can deal with martensite of various lath sizes.

Make models of the experiments that you analyzed, and couple the numerical model and the experimental data