Nuclear fusion power plants could provide a green, safe, compact, and continuous source of energy by transforming hydrogen isotopes into helium. However, no solid material can withstand the high temperature and particle flux released on the walls of the reactor. Consequently, the research group is exploring the use of a liquid metal surface supported by a 3D-printed porous tungsten structure that retains the liquid metal through capillary forces.

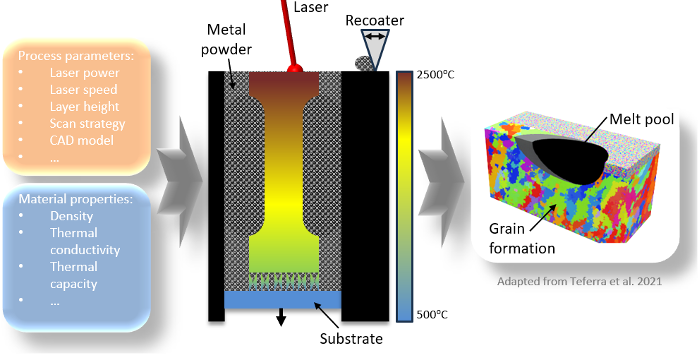

Additive Manufacturing (AM) is a remarkable technique used to fabricate components with near-net shape. Among the various AM methods, Laser Powder Bed Fusion (LPBF) stands out as a prominent process for fabricating metallic parts. In LPBF, a high-powered laser selectively melts layers of metal powder to build the component layer by layer, achieving complex geometries with high precision and material efficiency. The micrometric melt pool involves high thermal gradients and solidification rates. Tungsten, being a refractory material, has excellent properties for such applications, but its manufacturing using LPBF is very challenging.

Figure 1: Schematic representation of the Laser Powder Bed Fusion process

To better understand and optimize the scan parameters in Laser Powder Bed Fusion, a part-scale thermal model of the printing process is essential. This model will take printing parameters and material properties as inputs to model the heat input of each new layer and output the thermal field distribution throughout the part during fabrication. The resulting thermal data will be used by a PhD student to simulate crystal growth in the metal surrounding the melt pool, enabling deeper insights into microstructural evolution and material performance.

Your tasks will be:

1. Conduct a literature review on numerical modeling of the Laser Powder Bed Fusion process.

2. Develop a layer by layer thermal model of the part.

3. Validate the model using either literature data or experimental results.