Research Projects

Explore available research opportunities

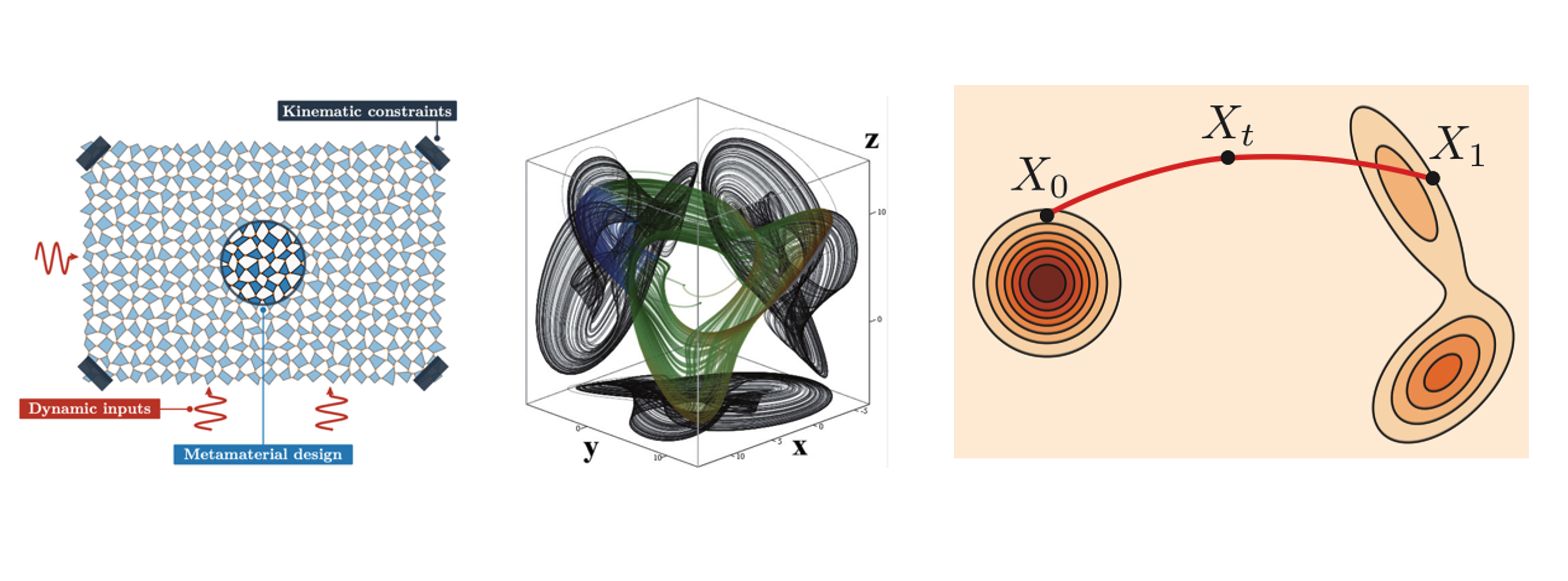

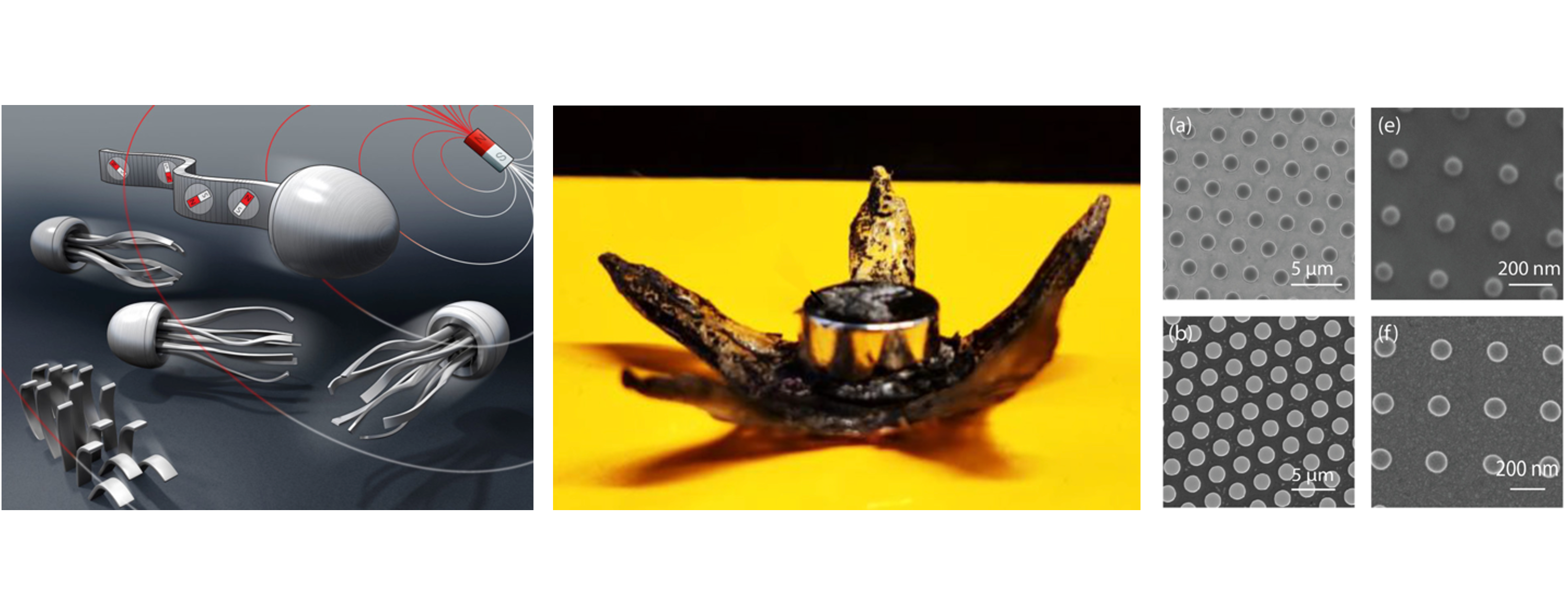

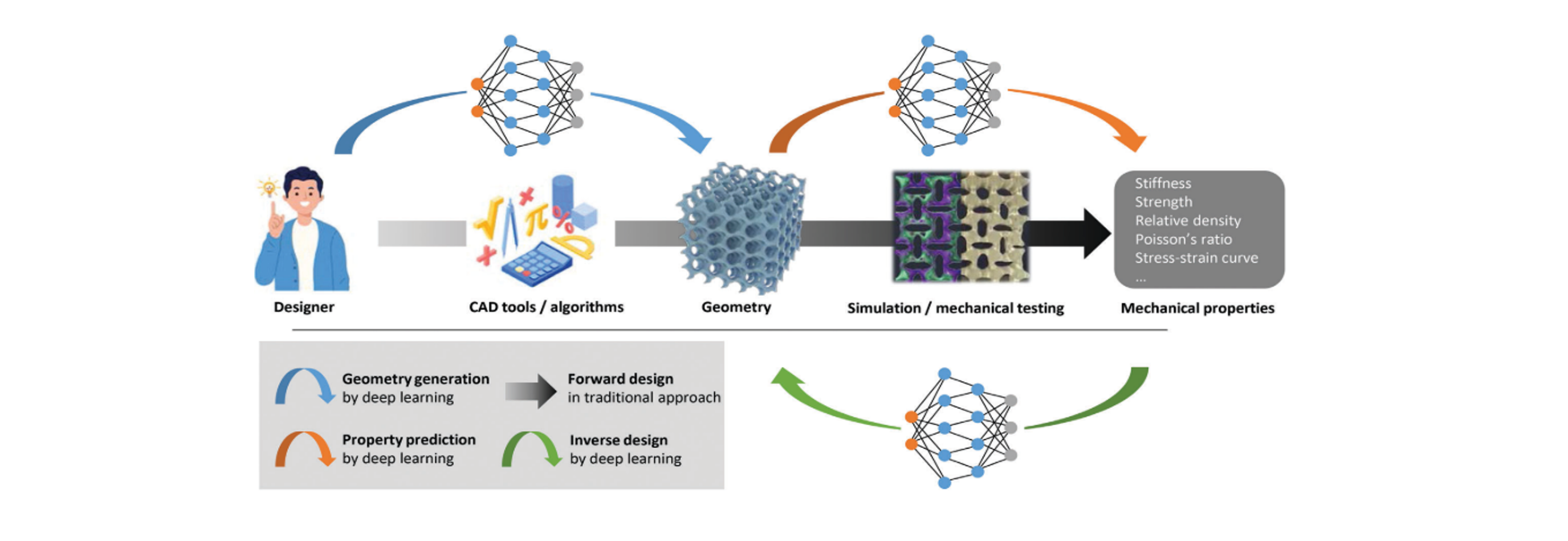

Regressing chaos through flow matching towards modelling and design of nonlinear dynamic metamaterials

Develop a machine-learning flow-matching algorithm, capable of predicting behavior of nonlinear dynamic metamaterials, allowing for design of new metamaterial structures.

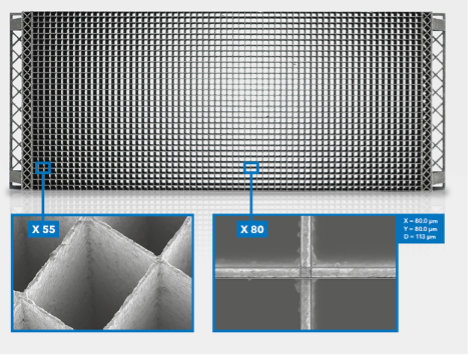

A comparative assessment of additive manufacturing methods for the production of pure tungsten

A comparative assessment of different additive manufacturing processes will be conducted for pure tungsten material.

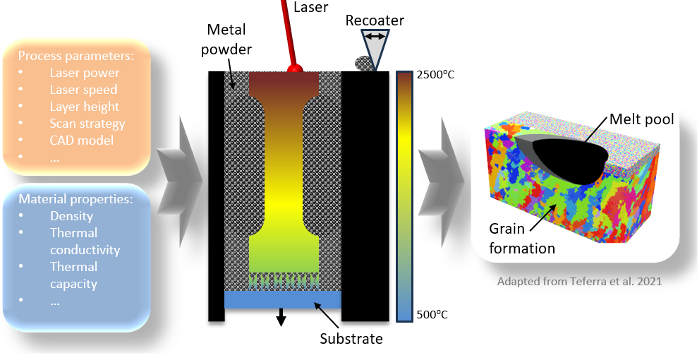

Numerical Study of Additively Manufactured Tungsten using LPBF for Fusion Applications

A part-scale model for additive manufacturing of tungsten components for nuclear fusion applications will be developed

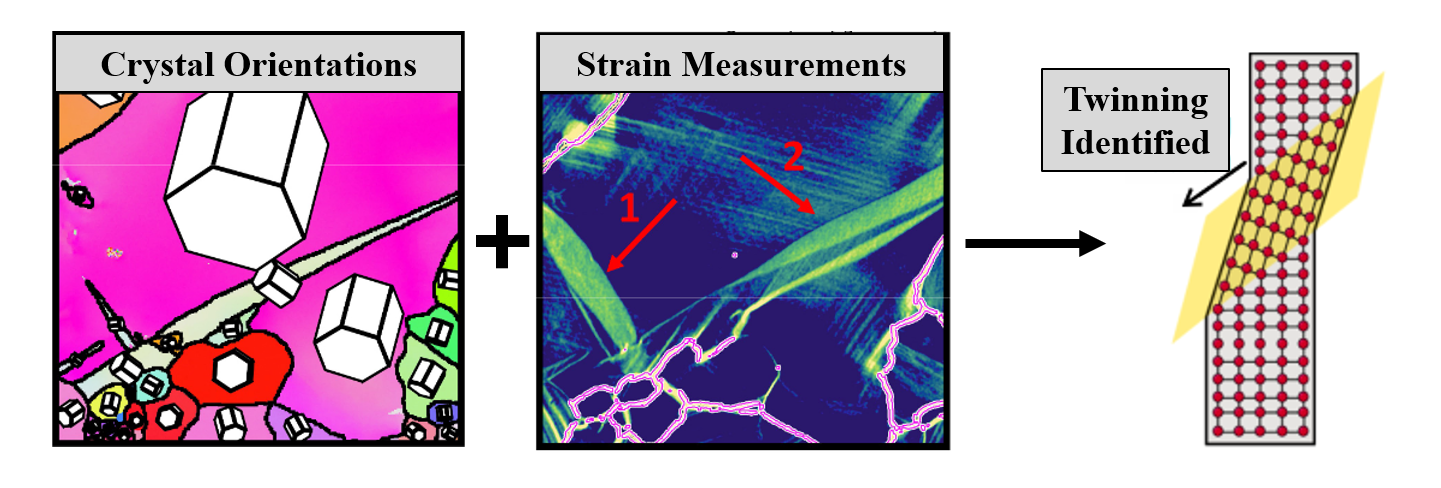

Automatic identification of “twinning” in metals on the microscale

Develop an automatic method to detect “twinning” in metals using high-resolution deformation (strain) maps and crystal orientation measurements. You’ll work with experimental & synthetic data, building on an existing Matlab slip-identification tool to design, test, and validate a new twinning-recognition approach.

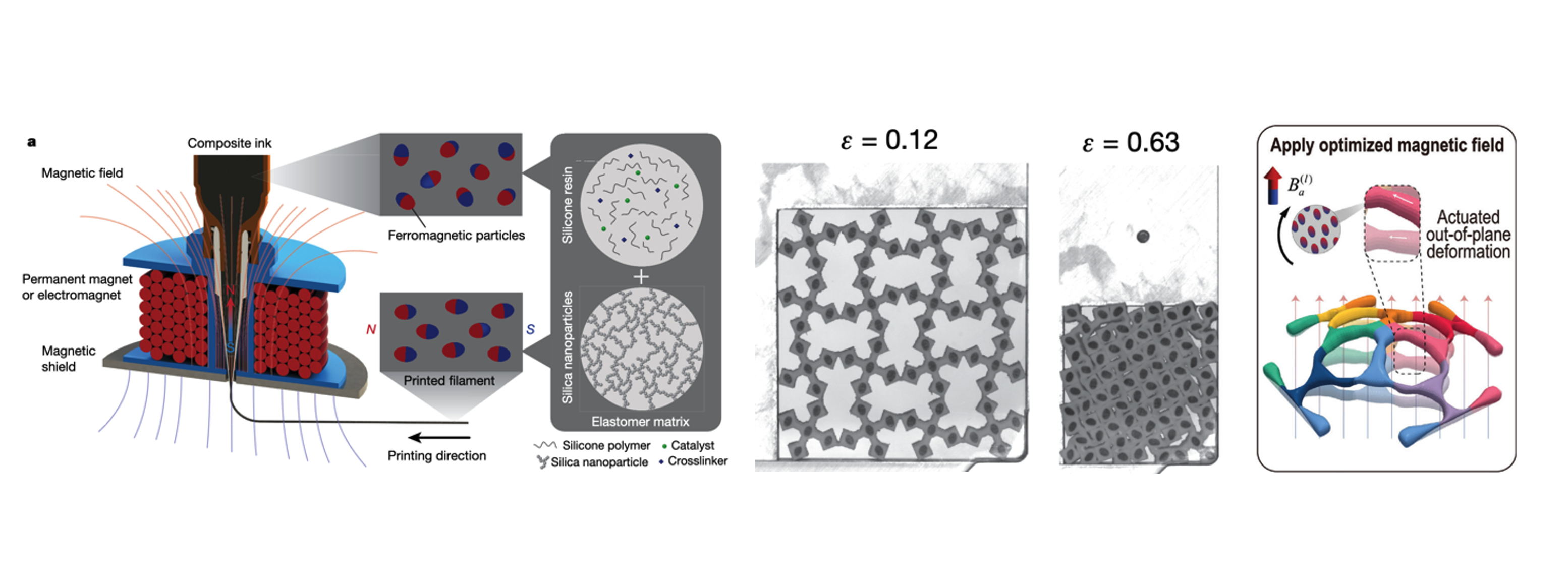

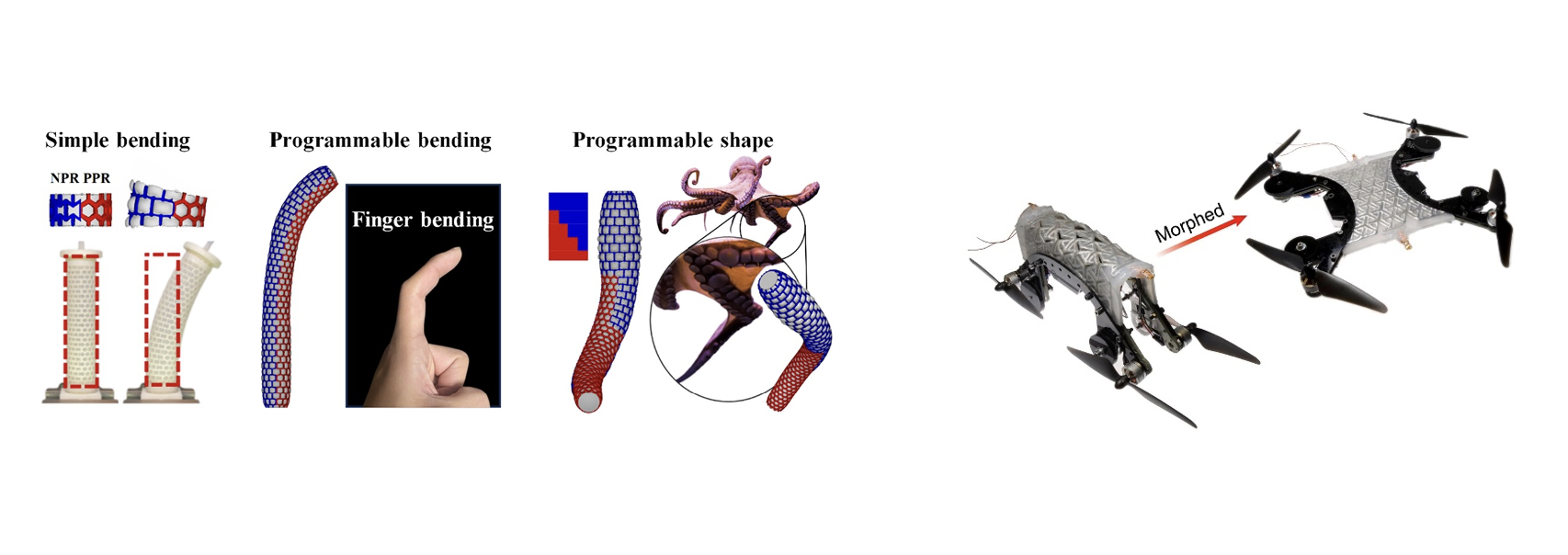

Design and manufacturing of 3D morphing scaffolds

Within this project, you will focus on computational design and additive manufacturing through 3D printing of shape-morphing scaffolds that can achieve desired shape change triggered by applications of external magnetic fields for applications in biomedical engineering.

Impact of post heat treatment on performance of 3D printed tungsten products

The impact of post heat treatment will be evaluated on microstructural and mechanical characteristics of 3D printed tungsten Anti scatter grids (ASG).

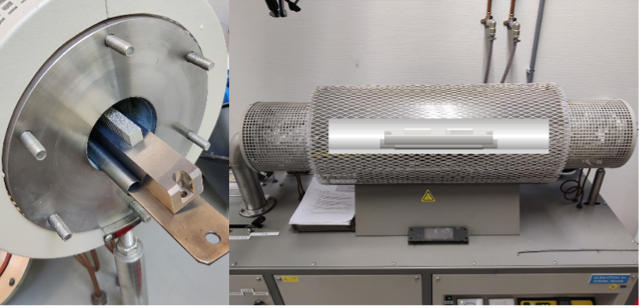

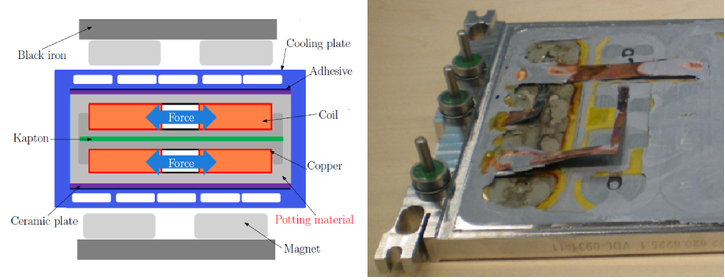

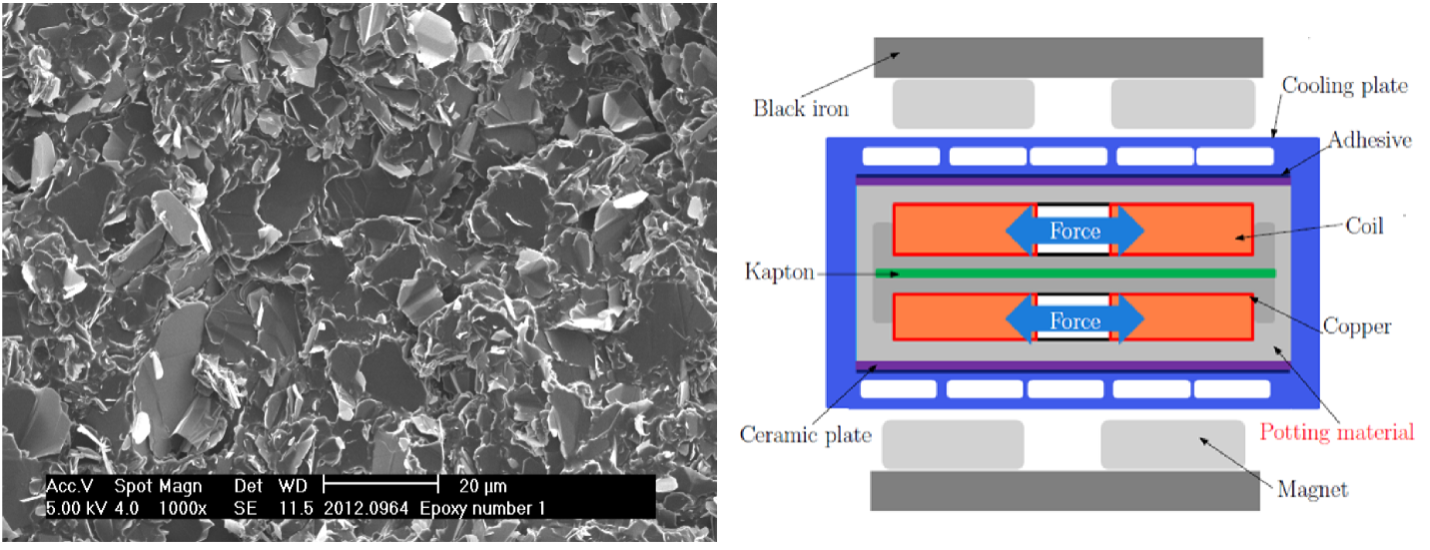

Characterization of potting material + interfaces in electromagnetic actuators

The microstructure and failure mechanisms of a potting material in electromagnetic actuators are experimentally investigated.

Development of effective constitutive model for polymers actuated by antiferromagnetic nanoplatelets

Develop of a novel constitutive material model that will accurately describe combined mechanical and magnetic behaviour of rubber materials with dispersed antiferromagnetic particles.

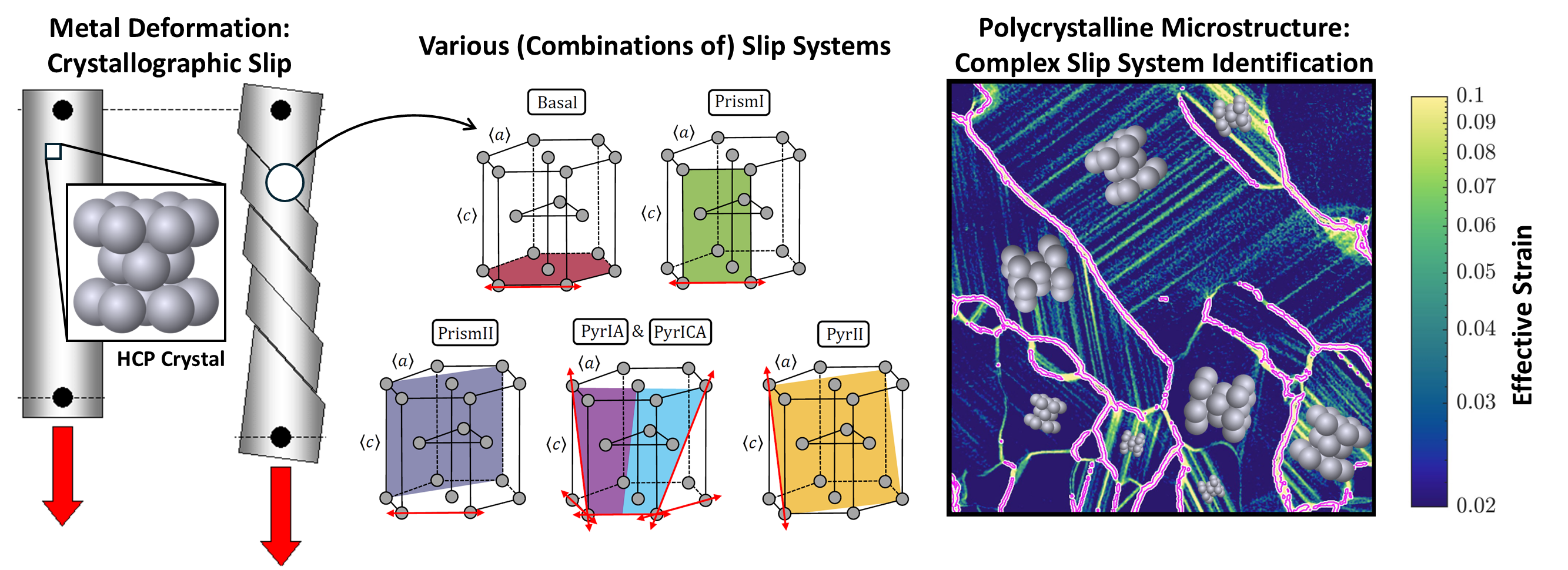

Materials meets Machine Learning - Identifying slip systems using neural networks

Identifying crystallographic slip systems in metals is critical to understand how they deform, so we can make them more durable and sustainable. Using machine learning, you will automate this process!

Micromechanical behavior of potting material for electromagnetic actuators

A fundamental understanding of the mechanical characteristics of the heterogeneous potting material in electromagnetic actuators is developed by the development and use of a numerical modelling framework.

Modelling plastic deformation in neutron irradiated aluminum alloys using mean field crystal plasticity

Microstructure evolution due to neutron irradiation of aluminum alloys used for structural components in nuclear research reactors is modelled

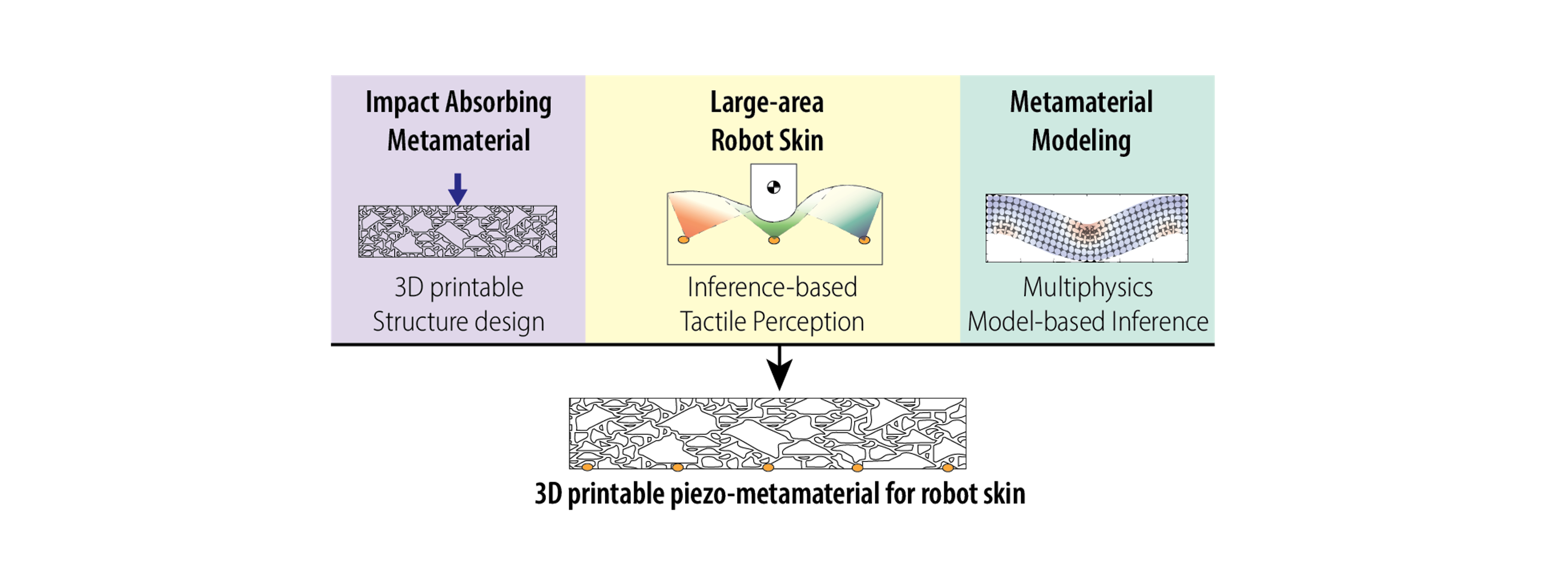

Metamaterial-Based Sensing Robot Skin

Design and development of a new class of robotic skins that will allow robots to sense and detect contact.

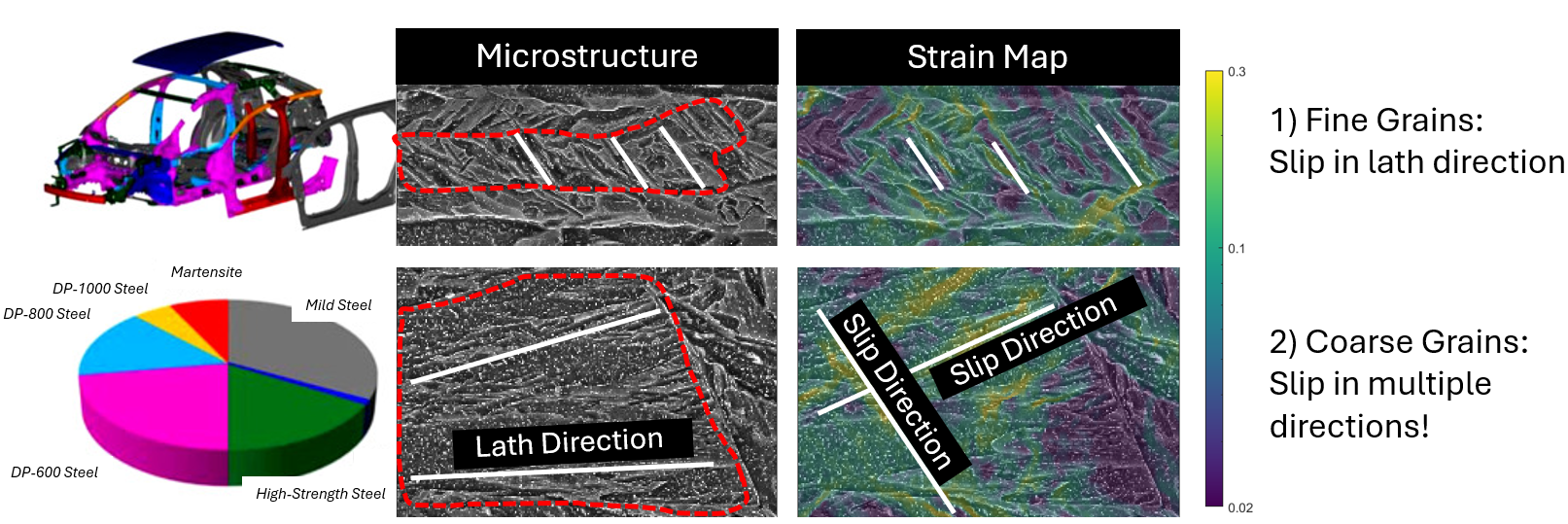

From experiment to simulation: uncovering the hidden anisotropy of martensite

Experiments show that martensite is anisotropic: its ductility strongly depends on the orientation of the crystal. Can you capture this behavior in a numerical model?

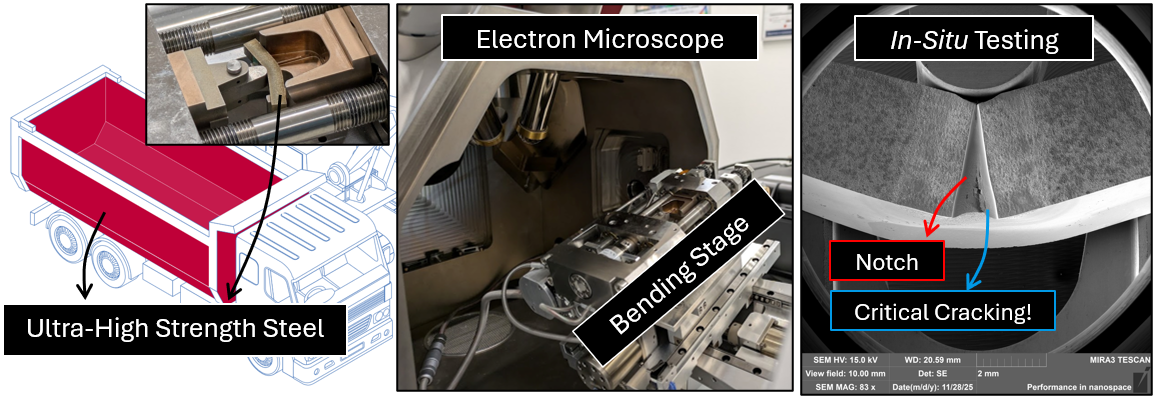

Bending at the microscale - a detailed experimental investigation

You will use high-resolution scanning electron microscopy to observe the complicated plasticity and damage evolution in high-strength steels, thereby contributing to the development of damage-resistant and sustainable steels.

Investigating energy absorption of semi-auxetic sandwich composites

Develop autoencoder architecture for inverse design of semi-auxetics optimised for energy absorption. You will first generate training dataset using finite element method, which will be subsequently used generate new geometries with maximum toughness.

Investigation of symmetry in mechanical metamaterials

Unraveling relationship between symmetry groups and (meta)material behavior. You will explore and understand the relationship between symmetry and mechanical properties of (meta)materials in relation to buckling.